Range Rover P38

ELECTRONIC AIR SUSPENSION

7

DESCRIPTION AND OPERATION

SYSTEM OPERATION

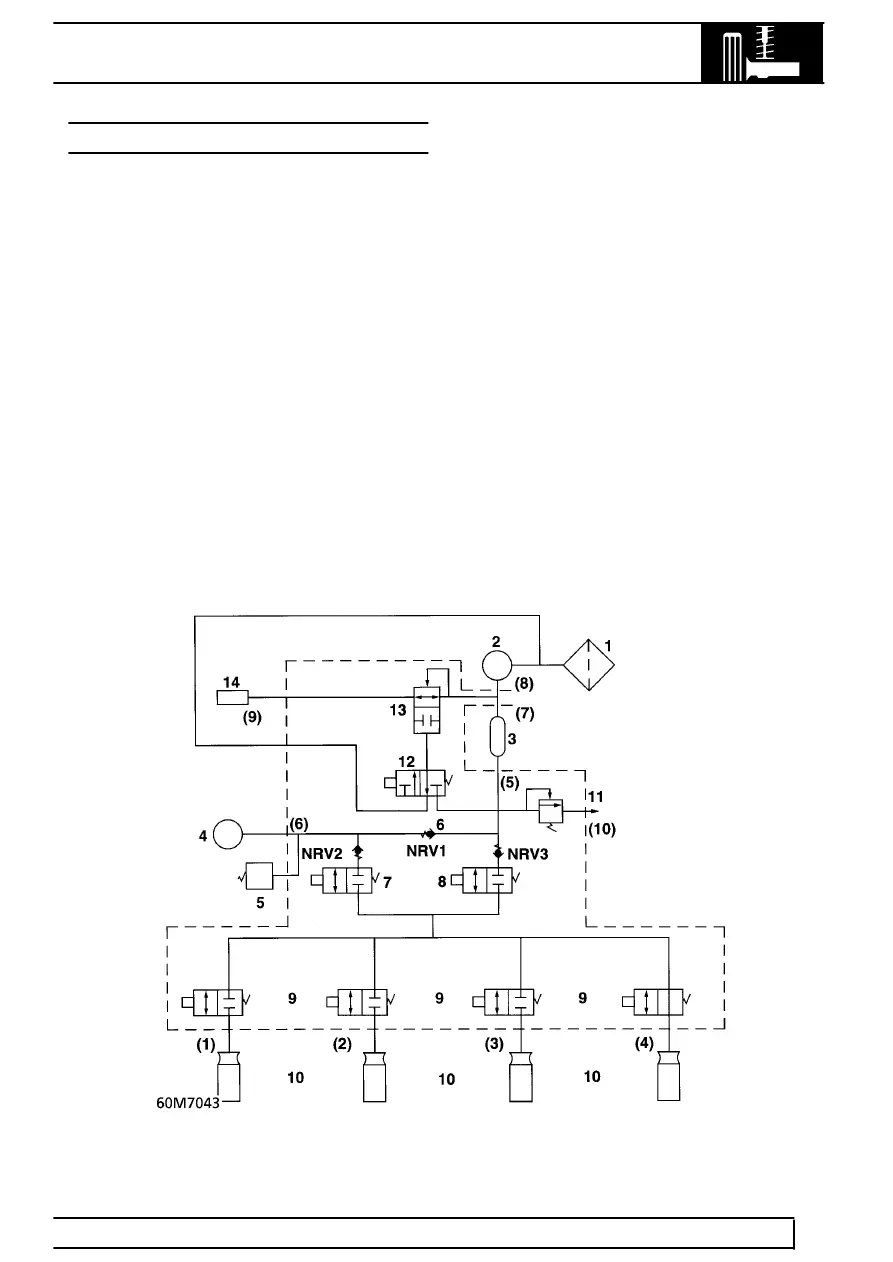

Numbers refer to pneumatic circuit diagram

Air is drawn through the inlet filter (1) to the

compressor (2), where it is compressed to 10

±

0,5

bar (145

±

7.25 lbf/in

2

).

Compressed air passes to the air dryer (3) where

moisture is removed as it flows through the dryer

dessicant. The dessicant in the lower portion of the

dryer becomes wet.

Dried air passes through a non-return valve NRV1 to

the reservoir (4).

The 3 non-return valves (6) ensure correct air flow.

They also prevent loss of spring pressure if total loss

of reservoir pressure occurs.

The pressure switch (5) maintains system pressure

between set limits by switching on and off the

compressor via an ECU controlled relay.

For air to be admitted to an air spring (10), the inlet

valve (7) must be energised together with the relevant

air spring solenoid valve (9).

For air to be exhausted from an air spring, the exhaust

valve (8) must be energised together with the relevant

air spring solenoid valve.

The solenoid diaphragm valve (12) ensures that all air

exhausted to atmosphere passses through the dryer.

Exhausted air passes vertically downwards through

the dryer. This action purges moisture from the

dessicant and regenerates the air dryer.

Air is finally exhausted through the system air

operated diaphragm valve (13) and to atmosphere

through a silencer (14) mounted below the valve

block.