Assembling Output and Layshaft to Center Plate - R380 Gearbox Overhaul

MANUAL GEARBOX

OVERHAUL

35

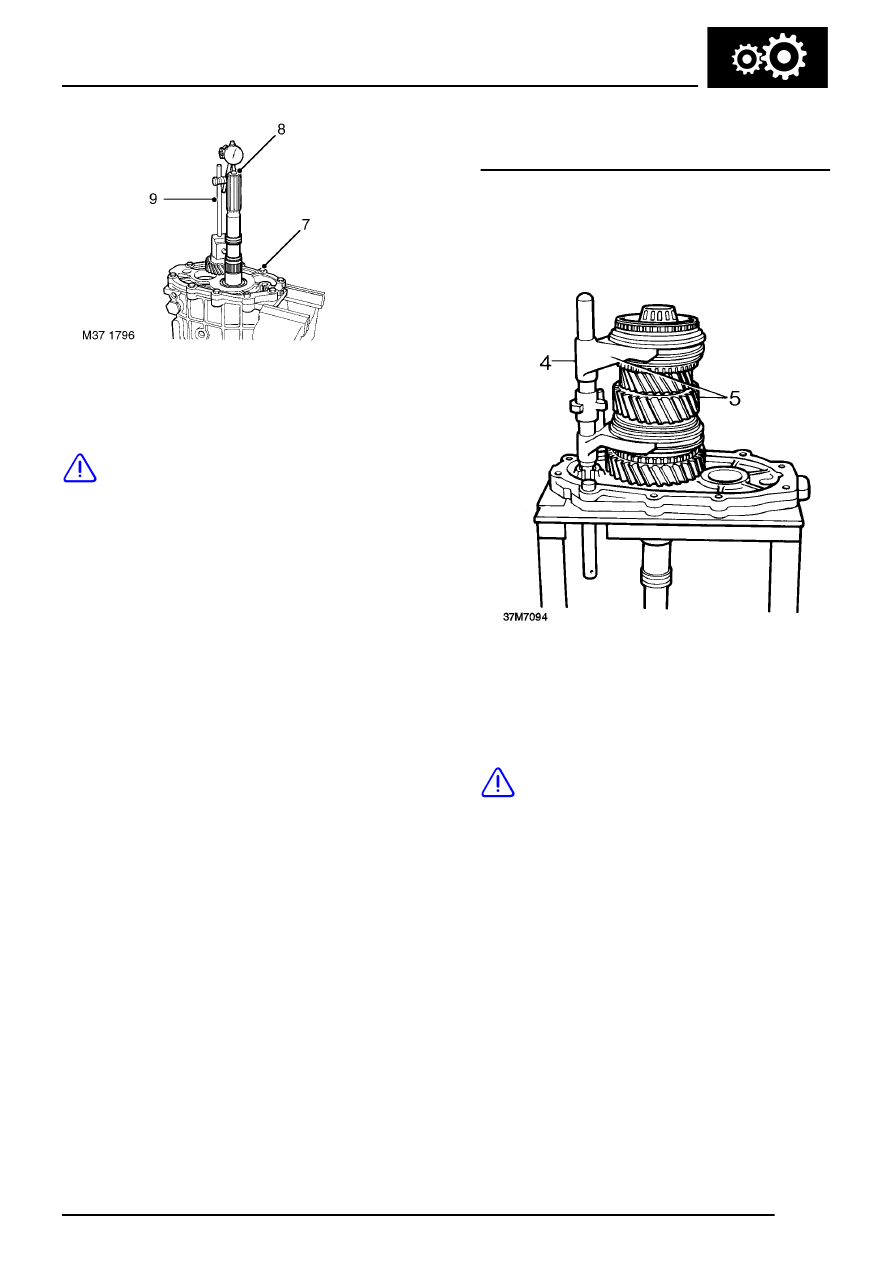

7. Fit centre plate and bolt down using 8 off 8 x

35 mm slave bolts.

CAUTION: Do not fit detent ball or spring

at this stage.

8. Fit large ball bearing to rear of output shaft.

9. Mount dial test indicator.

10. Rotate output shaft to settle bearings.

11. Lift output shaft and note DTI reading.

The end float setting for the output shaft and

layshaft is:-

Early gearboxes without suffix K added to serial

number:

New: 0.01 - 0.06 mm (0.0004 - 0.0024 in)

Service limit: 0.06 mm (0.0024 in)

Later gearboxes with suffix K added to serial

number:

New: 0.00 - 0.05 mm (0.00 - 0.002 in)

Service limit: 0.05 mm (0.002 in)

Shims to make up the required clearances are

placed under the respective bearing tracks in the

centre plate.

12. Dismantle and substitute shims if reading

incorrect.

13. Remove output shaft assembly and repeat

procedure for layshaft.

14. Remove centre plate, layshaft and output shaft.

15. Remove front cover.

16. Remove input shaft bearing track from front

cover, retain track with cover.

Assembling output shaft and layshaft to centre

plate

1. Secure centre plate to suitable workstand.

2. Fit selected shims and bearing tracks.

3. Fit lower detent ball and spring, use a dummy

bar to temporarily hold the ball in place.

4. Check both synchromesh units are in neutral

and fit selector shaft assembly to output shaft.

5. Fit output shaft and selectors as complete unit

to centre plate aligning pin with slot in plate.

CAUTION: Take care that as dummy shaft

is removed, detent spring and ball are not

displaced.

6. Fit 4th gear synchromesh baulk ring.