Range Rover Classic

17

EMISSION CONTROL

4

DESCRIPTION AND OPERATION

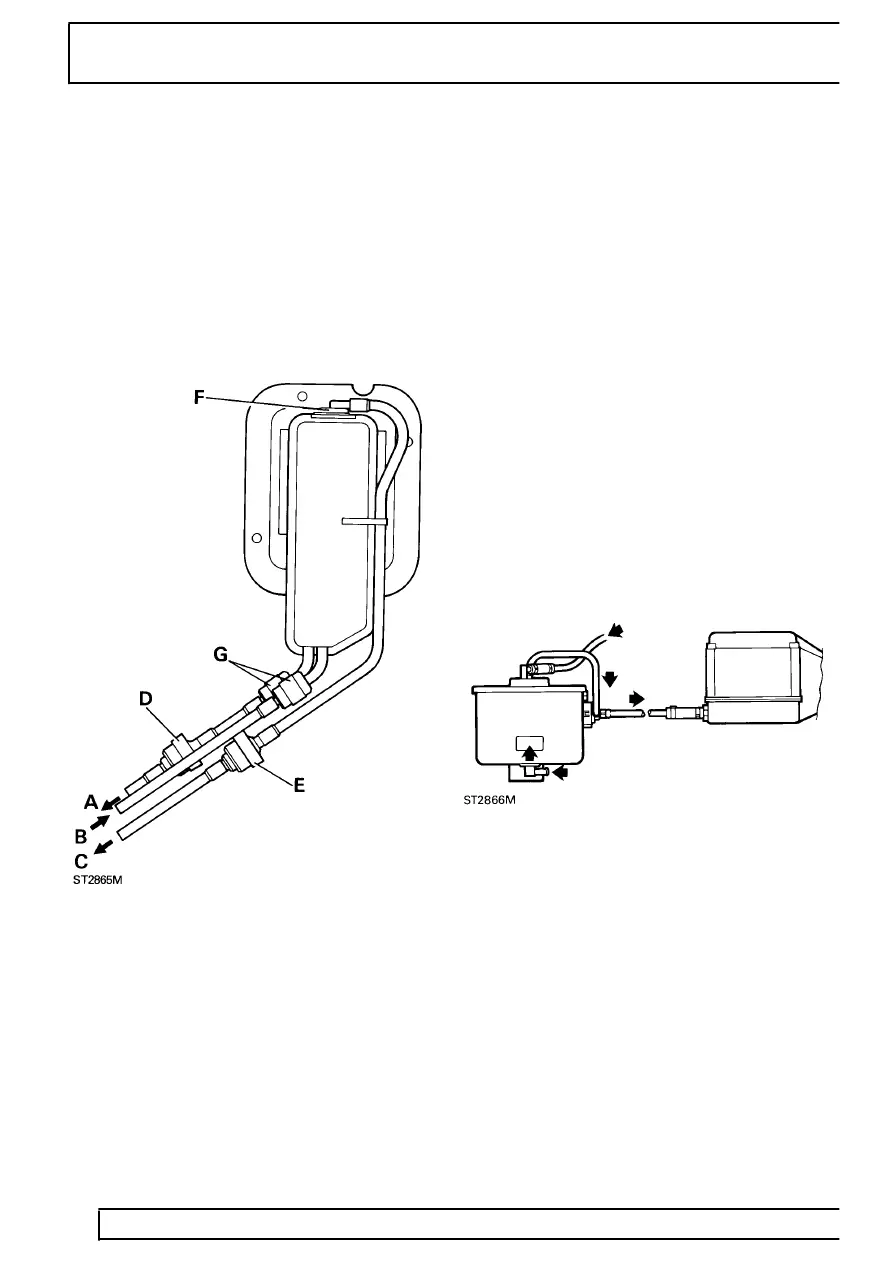

Evaporative emission control system.

The system is designed to prevent harmful fuel vapour

from escaping to the atmosphere. The system

consists of a vapour separator tank, connected to the

fuel tank and located between the body inner and

outer panels on the right hand side of the vehicle near

the rear wheel arch. An adsorbtion canister,

containing activated charcoal, is positioned in the

engine compartment attached to the front right

valance. The two components are connected by a

pipe running the length of the chassis.

A

Pressure relief to atmosphere.

B

From fuel tank to separator.

C

To adsorbtion canister.

D

Pressure relief valve.

E

Pressure relief valve.

F

Shut-off valve.

G

"Speed Fit" connectors.

A pressure relief valve is fitted in the hose which is

open to atmosphere. This valve acts as a safety valve

should a build-up of pressure occur in the system, for

example if a hose became blocked or kinked. The

volume of vapour emitted, in such an instance, would

be acceptable.

A pressure relief valve is also fitted in the hose

connected to the adsorbtion canister and releases

vapor to the canister when the pressure in the

separator reaches between 5 and 7 Kpa.

In the top of the separator a shut-off valve is

incorporated in the vapor exit port to prevent the

possible presence of any liquid fuel being transmitted

to the adsorbtion canister should the vehicle roll over.

The adsorbtion canister, which is connected by a hose

to the plenum chamber, absorbs and stores the fuel

vapour from the fuel tank while the engine is not

running. When the engine is started, the vapour is

purged from the canister by air drawn through an

orifice in the base of the canister and by the influence

of vacuum at the top. The vapour drawn into the

plenum chamber through a solenoid operated purge

valve is finally burnt in the combustion chambers.

The purge valve, which is attached to the adsorbtion

canister support bracket, is controlled by the Engine

Control Module ECM which determines the most

emission acceptable time at which purging should

take place. This will normally be at engine speeds

above idle and when the vehicle is in motion. A signal

from the ECM to the purge valve operates the

solenoid and opens the valve to purge the canister of

fuel vapour.