Range Rover Classic

54

FRONT AXLE AND FINAL DRIVE

10

OVERHAUL

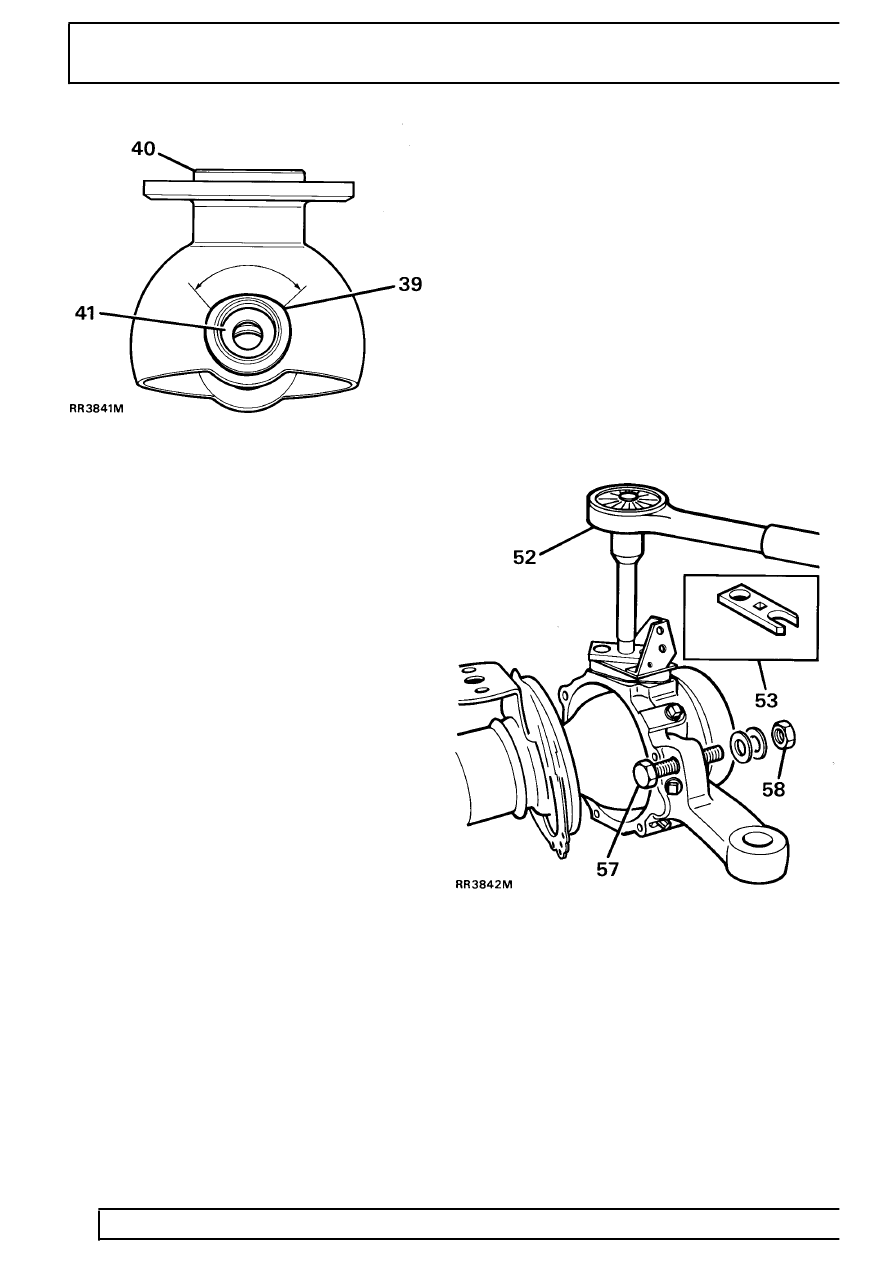

40. With seal lips trailing press axle shaft oil seal

flush into rear of housing. Grease lips.

41. Fit new thrust washers and bearing into top

swivel pin bush.

42. Hang swivel pin bearing housing oil seal and

retainer plate over back of housing. Ensure they

are in correct assembly order.

43. Fit a new joint washer and secure swivel pin

bearing housing to axle. Starting with top fixing

dowel bolt. Tighten to

72Nm.

Fit swivel pin housing

44. Grease and fit lower swivel pin bearing to

bearing housing.

45. Place swivel pin housing in position over swivel

pin bearing housing.

46. Using a new joint washer, fit lower swivel pin

with lip outboard. Do not secure with screws at

this stage.

47. Fit a new sensor bush and new oil seal, lip side

leading to top swivel pin.

48. Lubricate with a recommended oil and fit top

swivel pin with existing shims.

49. Coat threads of top swivel pin bolts with Loctite

542. Fit bolts and jump hose bracket (do not

tighten).

50. Coat threads of lower swivel pin screws with

Loctite 270 and fit, together with damper and

shield bracket. Tighten to

25 Nm.

51. Tighten top swivel pin and brake jump hose

bracket securing bolts to

65 Nm.

Check and adjust preload on bearings

52. The preload on bearings to be 0,25 to 0,30 mm,

without swivel housing oil seal and axle fitted,

and reading from centre of swivel pin. The

torque required to turn swivel assembly from

lock to lock to be

2.0 to 2.8 Nm. Adjust by

removing or adding shims as necessary.

53. To take a reading use special tool LRT-57-024

torque test adaptor, with a torque wrench and

extension as shown.

54. Apply a recommended grease between lips of

swivel housing oil seal.

55. Secure oil seal with retaining plate and securing

bolts. Tighten to

11Nm.

56. Fit track-rod and drag link and secure with new

cotter pins.

57. Loosely fit lock stop bolt for later adjustment.

58. Fit brake disc shield.