Checking Camshaft End-Float in Engine Overhaul Manual v8

ENGINE

OVERHAUL

29

Oil pressure relief valve if fitted - refit

1. Lubricate new ’O’ ring with engine oil and fit to

relief valve plug.

2. Lubricate relief valve spring, piston and piston

bore with engine oil.

3. Assemble piston to relief valve spring, insert

piston and spring into piston bore.

4. Fit relief valve plug, depress plug and fit circlip.

5. Ensure circlip is fully seated in groove.

CAMSHAFT AND TAPPETS

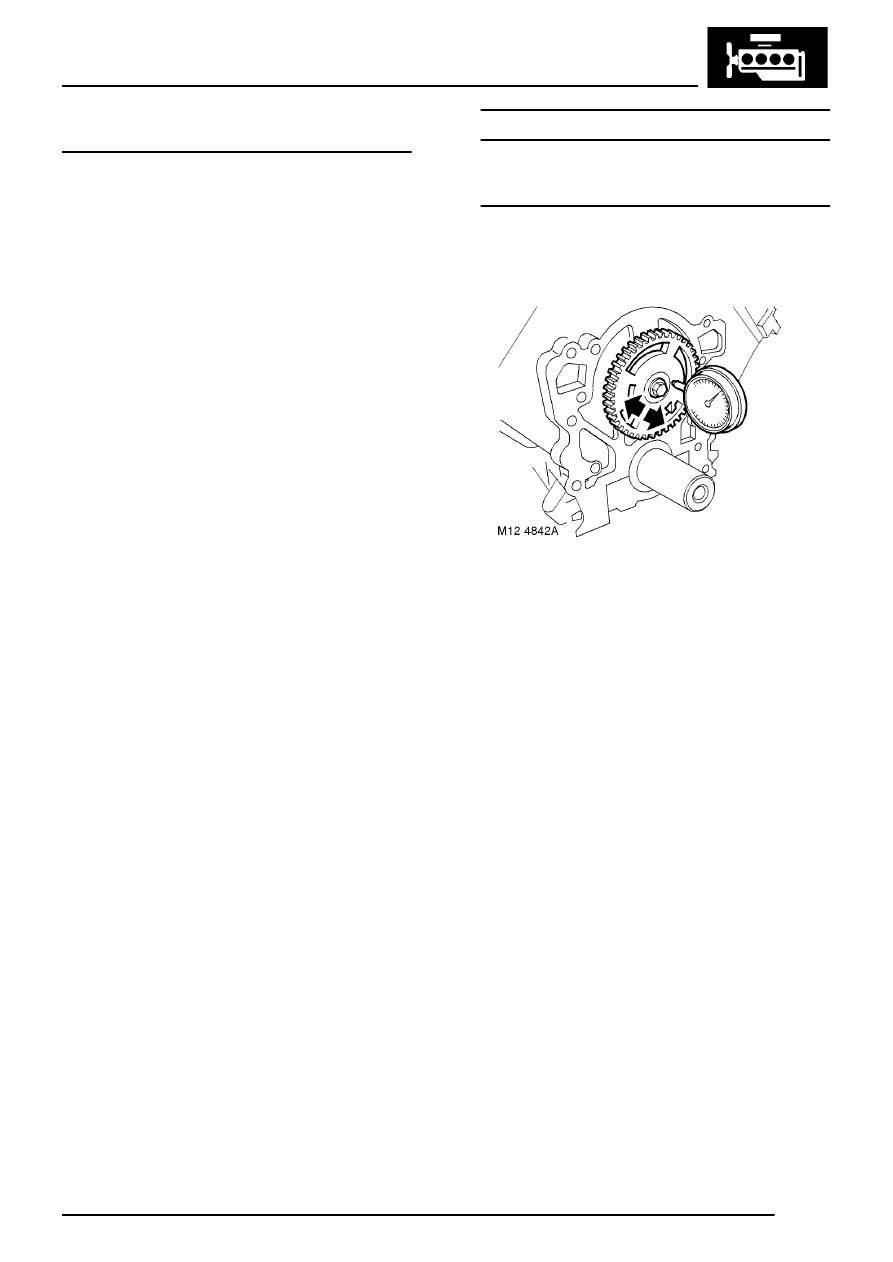

Camshaft end-float - check

1. Remove rocker shaft assemblies.

2. Remove pushrods and store in their fitted

order.

3. Remove timing chain and gears.

4. Temporarily fit camshaft gear and gear bolt.

5. Attach a suitable DTI to front of cylinder block

with stylus of gauge contacting camshaft gear.

6. Push camshaft rearwards and zero gauge.

7. Using camshaft gear bolt, pull camshaft

forwards and note end-float reading on gauge.

End-float = 0.05 to 0.25 mm (0.002 to 0.010 in)

8. If end-float is incorrect, fit a new thrust plate

and re-check. If end-float is still incorrect, a

new camshaft must be fitted.