Engine Overhaul Manual v8 40 46 - Crankshaft end float check

ENGINE

52

OVERHAUL

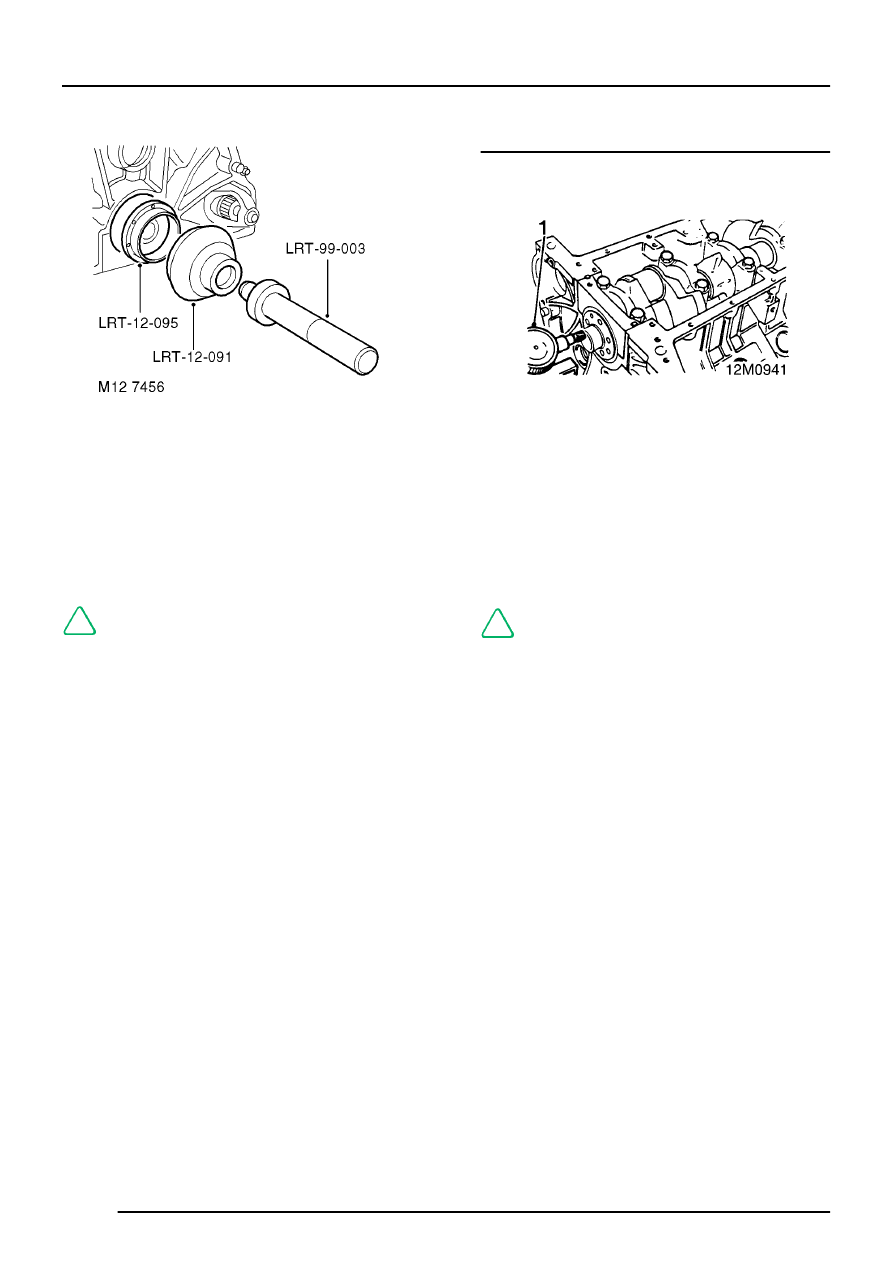

17. Position seal protector LRT-12-095 to

crankshaft.

18. Fit seal using tools LRT-12-091 and

LRT-99-003 .

19. Remove seal protector LRT-12-095 .

20. Fit Woodruff key to crankshaft.

21. Check crankshaft end-float.

NOTE: If 0.508 mm (0.02 in) oversize main

bearings have been fitted, it may be

necessary to machine thrust faces of

crankshaft centre main bearing location to

achieve correct end-float. Ensure an equal

amount of material is removed from each thrust

face.

22. Fit big-end bearings.

23. Fit timing chain and gears.

24. Fit timing cover.

25. Fit flywheel or drive plate and ring gear

assembly.

Crankshaft end - float - check

1. Set-up DTI to measure end float.

2. Move crankshaft forwards and zero gauge.

3. Move crankshaft rearwards, record end-float

reading obtained.

Crankshaft end-float = 0.08 to 0.26 mm (0.003

to 0.010 in).

4. Remove DTI.

NOTE: Crankshaft end-float is controlled

by thrust faces on upper half of centre

main bearing shell. If crankshaft has been

reground and 0.508 mm (0.02 in) oversize main

bearing shells are to be fitted, it may be

necessary to machine thrust faces of crankshaft

centre main bearing journal to achieve correct

end-float. Ensure an equal amount of material is

removed from each thrust face.