Removing Crankshaft from Engine Overhaul Manual v8 40 46

ENGINE

46

OVERHAUL

8. Check clearance between connecting rods on

each crankshaft journal.

Connecting rod clearance = 0.15 to 0.36 mm

(0.006 to 0.014 in).

9. Clean oil strainer and oil pick-up pipe.

10. Smear a new ’O’ ring with engine oil and fit to

oil pick-up pipe.

11. Position oil pick-up pipe spacer on number 4

main bearing cap stud.

12. Fit oil pick-up pipe ensuring that end of pipe is

correctly inserted in oil pump body.

13. Fit oil pick-up pipe to oil pump body bolts and

tighten to 8 Nm (6 lbf.ft).

14. Fit washers and nut securing oil pick-up pipe to

stud; tighten nut to 24 Nm (18 lbf.ft).

15. Fittiming chain and gears.

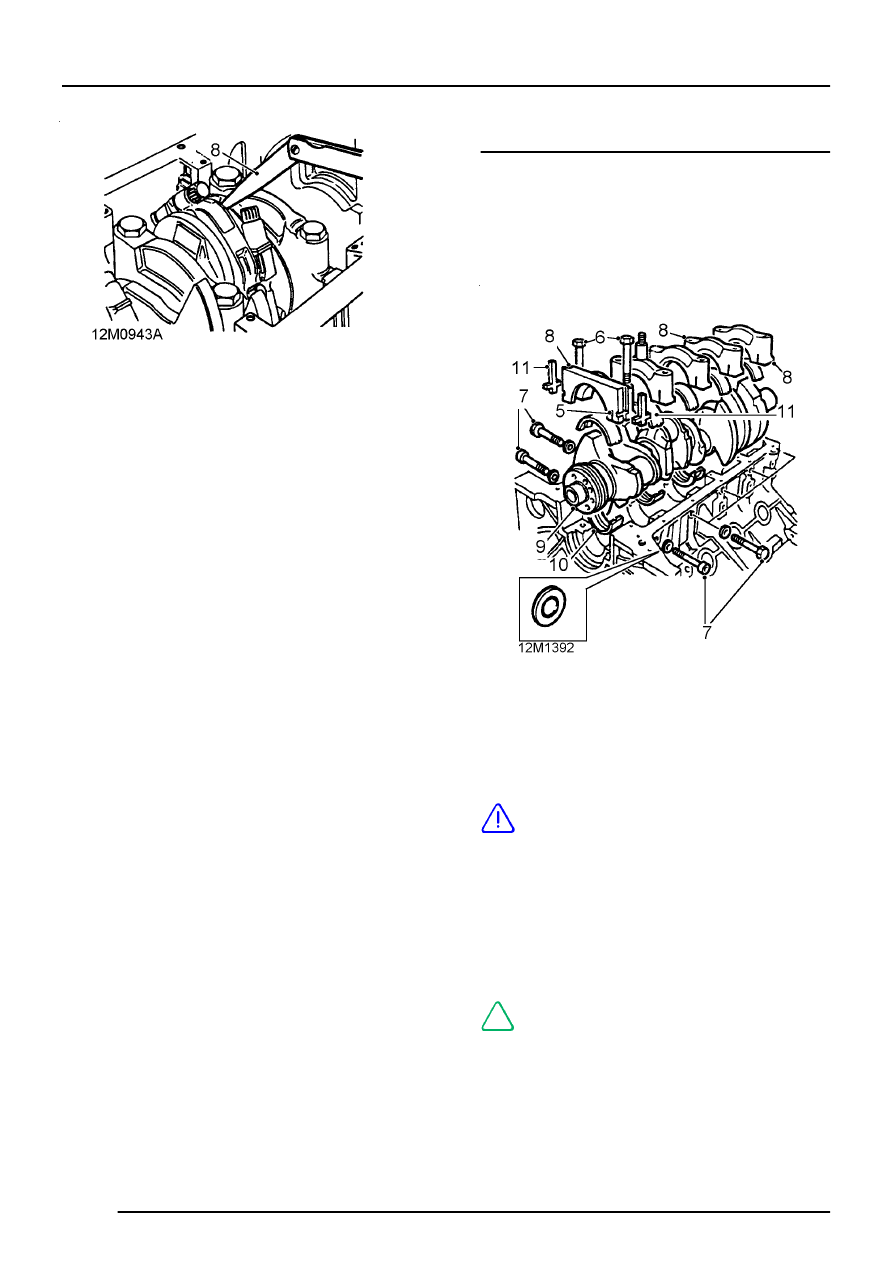

Crankshaft - remove

1. Remove flywheel or drive plate and ring gear

assembly.

2. Remove timing cover.

3. Remove timing chain and gears.

4. Remove big-end bearings.

5. Make suitable reference marks between each

main bearing cap and cylinder block.

6. Starting at centre main bearing and working

outwards, progressively slacken then remove

10 main bearing cap bolts.

CAUTION: Keep bolts in their fitted order.

7. Starting at centre main bearing and working

outwards, progressively slacken then remove 5

LH side hexagonal head bolts and 4 RH side

hexagonal head bolts and one Allen bolt;

remove and discard Dowty washers.

8. Remove 5 main bearing caps, remove and

discard bearing shells.

NOTE: Number 4 main bearing cap is

drilled to accommodate oil pick-up pipe

stud.