Engine Overhaul Manual: Refitting the Sump for v8 40 46 Engine

ENGINE

OVERHAUL

21

Sump - refit

Early engines fitted with pressed steel sump

1. Remove all traces of old sealant from mating

faces of cylinder block and sump, ensure bolt

holes are clean and dry.

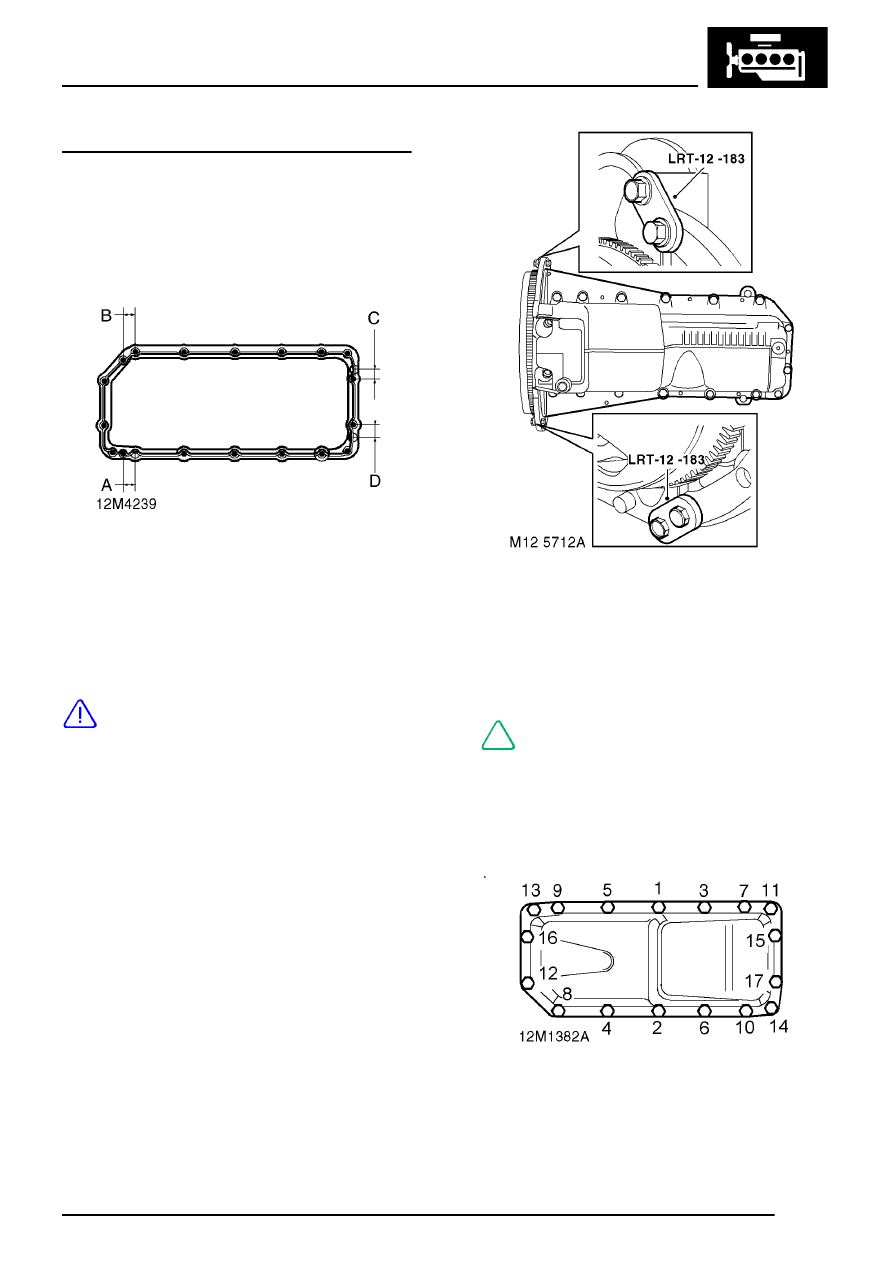

2. Apply a bead of sealant, Part number STC

50550 to sump joint face as shown:

Bead width - areas A, B, C and D = 12 mm (0.5

in)

Bead width - remaining areas = 5 mm (0.20 in)

Bead length - areas A and B = 32 mm (1.23 in)

Bead length - areas C and D = 19 mm (0.75 in)

CAUTION: Do not spread sealant bead.

Sump must be fitted immediately after

applying sealant.

3. Apply a globule of the sealant to cover the

ends of the cruciform seals.

4. Noting that the two parts of the tool are

’handed’, fit tool LRT-12-183 to the engine

backplate using slave bolts.

5. Secure the tool to the sump using the bolts

which are part of the tool.

NOTE: The holes in the tool are larger than

the diameter of the bolts in order to allow

the sump to move as the sump bolts are

tightened.

6. Fit sump, taking care not to damage sealant

bead.

7. Fit sump bolts and nuts and working in

sequence shown, tighten to 23 Nm (17 lbf.ft).

8. Remove tool LRT-12-183 .