V8 Engine: Description and Operation for 35, 39, and 42 Models

ENGINE

8

DESCRIPTION AND OPERATION

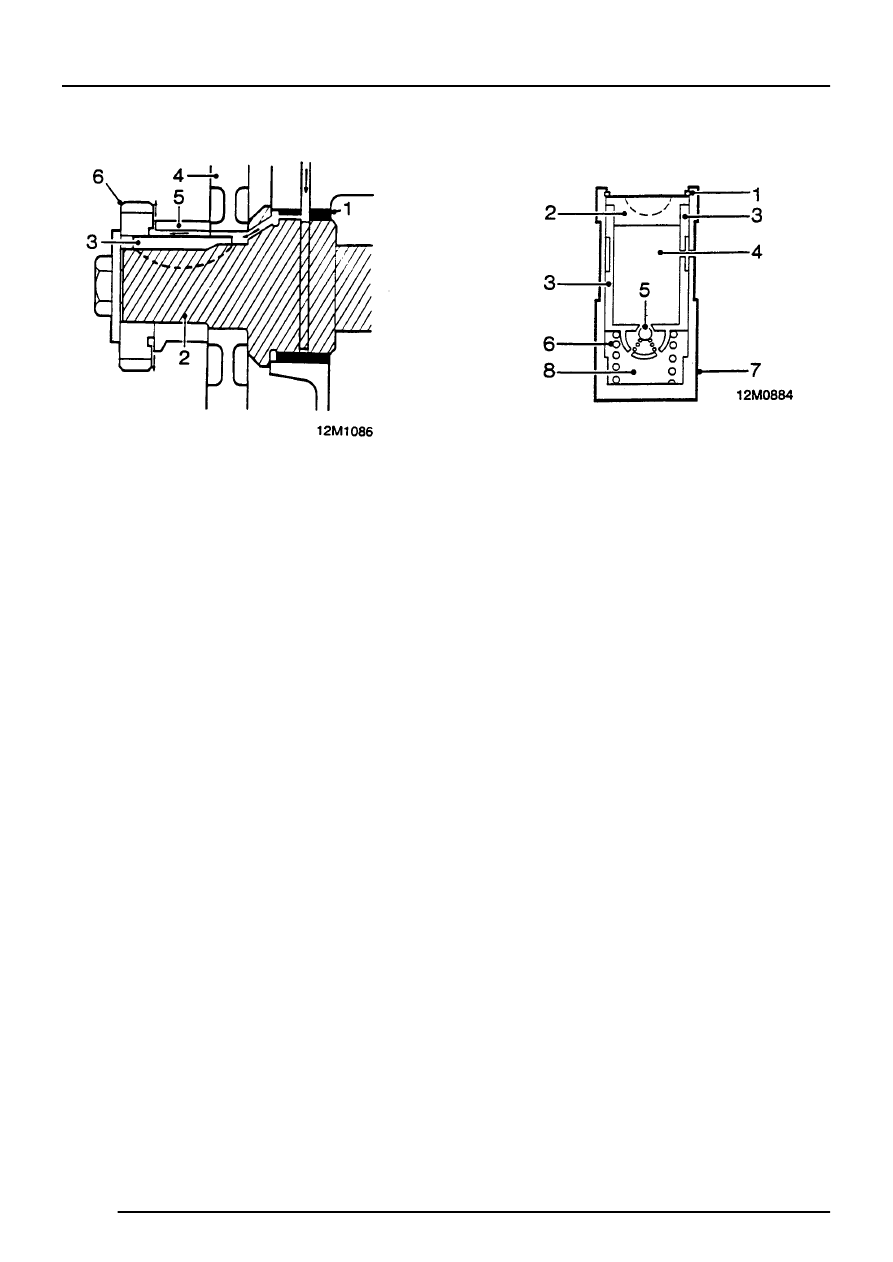

Distributor drive and timing chain lubrication

1. Bearing

2. Camshaft

3. Key

4. Camshaft timing chain sprocket

5. Spacer

6. Distributor drive gear

The distributor drive and timing chain are lubricated

from the camshaft front bearing. The feed to the

timing chain is channelled along the camshaft

sprocket, key and spacer.

Hydraulic tappets

1. Clip

2. Pushrod seat

3. Inner sleeve

4. Upper chamber

5. Non-return ball valve

6. Spring

7. Outer sleeve

8. Lower chamber - high pressure

The purpose of the hydraulic tappet is to provide

maintenance free and quiet operation of the inlet

and exhaust valves. It achieves this by utilising

engine oil pressure to eliminate the mechanical

clearance between the rockers and the valve stems.

During normal operation, engine oil pressure present

in the upper chamber passes through the non-return

ball valve and into the lower, high pressure,

chamber.

When the cam begins to lift the outer sleeve, the

resistance of the valve spring felt through the push

rod and seat causes the tappet inner sleeve to move

downwards inside the outer sleeve. This downward

movement of the inner sleeve closes the ball valve

and increases the pressure in the lower, high

pressure chamber, sufficiently to ensure that the

push rod opens the valve fully.

As the tappet moves off the peak of the cam the ball

valve opens to equalise the pressure in both

chambers which ensures the valve closes when the

tappet is on the back of the cam.