Inspecting Camshaft and Tappets for V8 Engine Overhaul

ENGINE

34

OVERHAUL

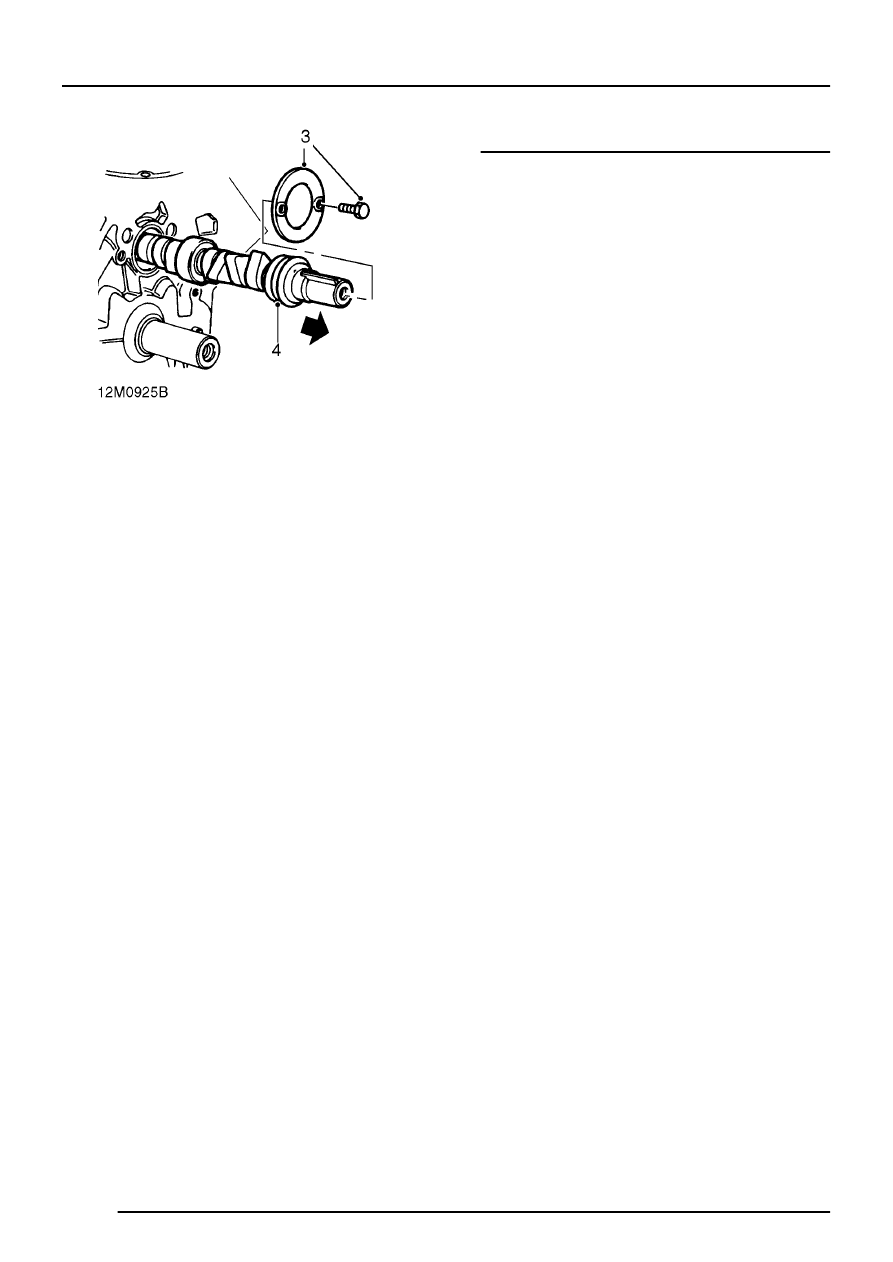

3. Remove 2 bolts securing camshaft thrust plate

- if fitted to cylinder block, remove plate.

4. Withdraw camshaft, taking care not to damage

bearings in cylinder block.

Camshaft and tappets - inspection

1. Throughly clean all components.

2. Inspect camshaft bearing journals and lobes

for signs of wear, pitting, scoring and

overheating.

3. Support camshaft front and rear bearings on

vee blocks, and using a DTI, measure

camshaft run-out on centre bearing.

Maximum permitted run-out = 0.05 mm (0.002

in).

4. Inspect camshaft thrust plate - if fitted, for

wear, replace plate if wear is evident.

5. Clean and inspect tappets. Check for an even,

circular wear pattern on the camshaft contact

area. If contact area is pitted or a square wear

pattern has developed, tappet must be

renewed.

6. Inspect tappet body for excessive wear or

scoring. Replace tappet if scoring or deep wear

patterns extend up to oil feed area. Clean and

inspect tappet bores in engine block.

7. Ensure that tappets rotate freely in their

respective bores.

8. Inspect push rod contact area of tappet,

replace tappet if surface is rough or pitted.