Refitting Cylinder Head for V8 Engines 35, 39, and 42: Overhaul Guide

ENGINE

14

OVERHAUL

Cylinder head - refit

1. Clean cylinder block faces using a suitable

gasket removal spray and plastic scraper;

ensure that bolt holes in cylinder block are

clean and dry.

CAUTION: Do not use metal scraper or

machined surfaces may be damaged.

2. Engine numbers without suffix B: Thoroughly

clean threads of cylinder head bolts.

CAUTION: Cylinder head bolts fitted to

engines without suffix B added to serial

number are not interchangeable with

those fitted to engines with suffix B added to

serial number.

3. Fit cylinder head gasket with the word ’TOP’

uppermost.

NOTE: Gasket must be fitted dry.

CAUTION: Engines without suffix B have a

steel gasket whilst engines with suffix B

have a composite gasket. The two types of

gasket are not interchangeable and it is essential

to ensure that the correct type of gasket is fitted.

4. Carefully fit cylinder head and locate on

dowels.

Engine numbers without suffix B

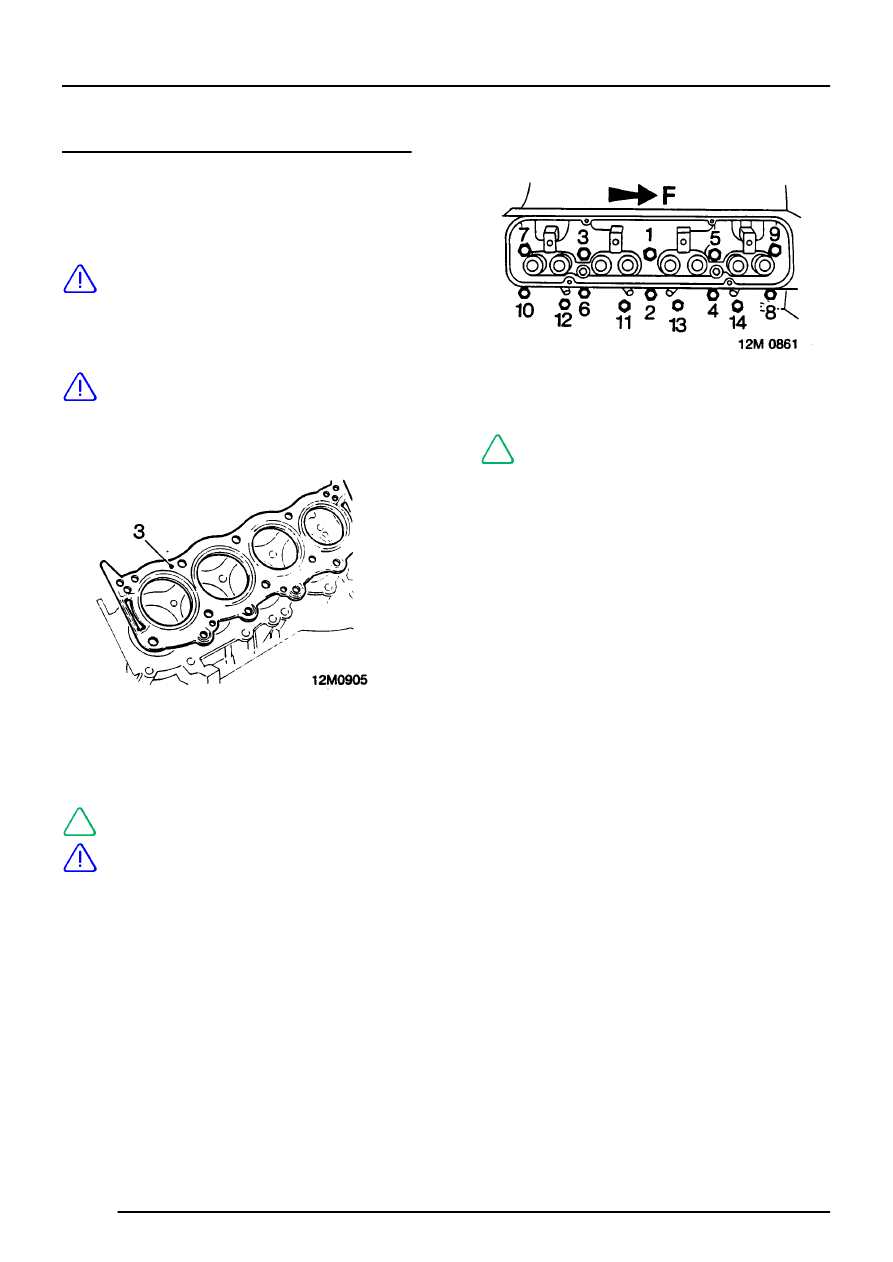

NOTE: RH cylinder head illustrated

5. Lightly oil threads of cylinder head bolts.

6. Fit cylinder head bolts:

Long bolts: 1, 3 and 5.

Medium bolts: 2, 4, 6, 7, 8, 9, and 10.

Short bolts: 11, 12, 13 and 14.

7. Using sequence shown, progressively tighten

cylinder head bolts to:

Bolts 11 to 14 - Outer row - 60 Nm (44 lbf.ft)

Bolts 2, 4, 6, 8 and 10 - Centre row - 90 Nm

(66 lbf.ft)

Bolts 1, 3, 5, 7 and 9 - Inner row - 90 Nm (66

lbf.ft)