Checking Height of Drive Plate and Ring Gear Assembly during V8 Engine Overhaul

ENGINE

OVERHAUL

45

Drive plate and ring gear - inspection

1. Inspect drive plate for cracks and distortion.

2. Renew drive plate if necessary.

3. Inspect ring gear for worn, chipped and broken

teeth.

4. Renew ring gear assembly if necessary.

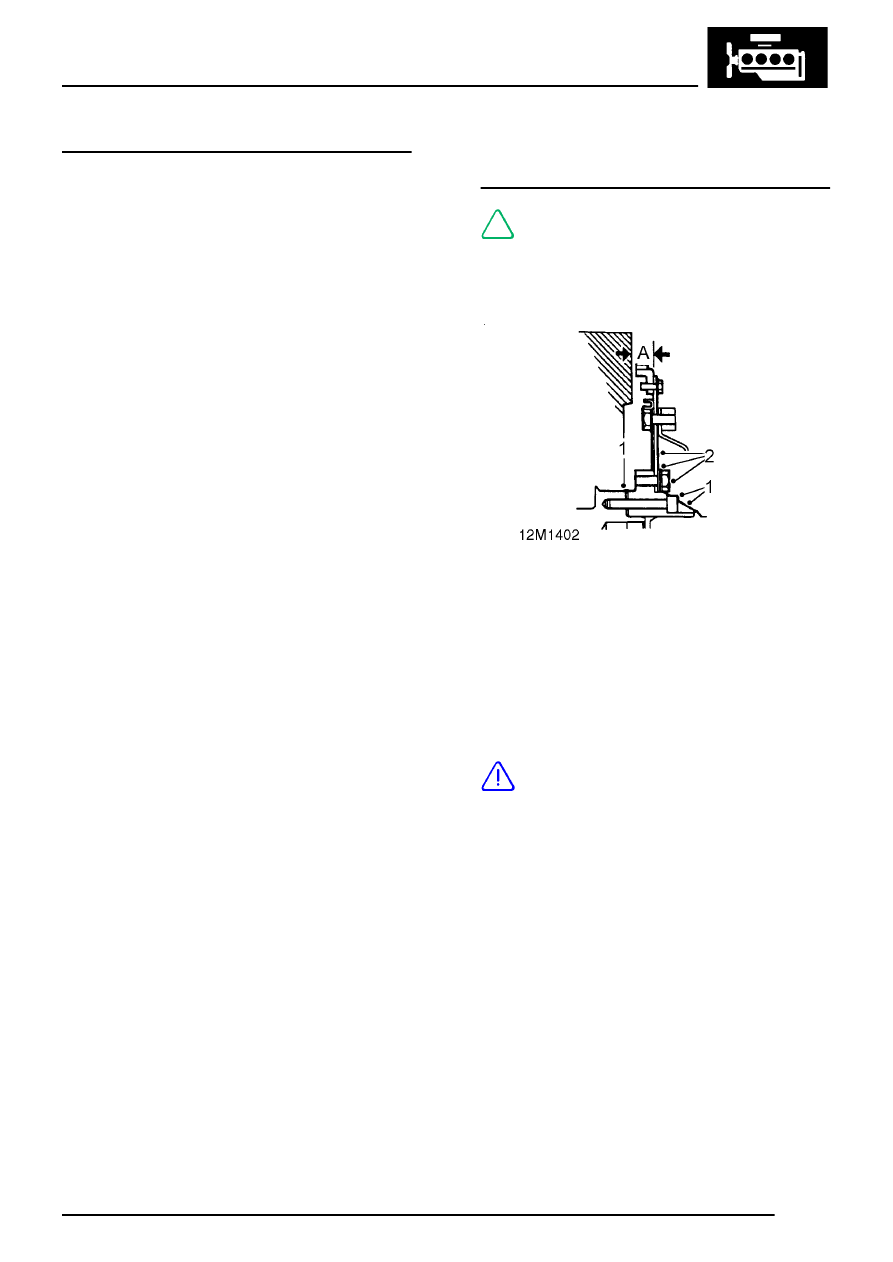

Drive plate and ring gear assembly - check

setting height

NOTE: The following procedures are only

applicable to shimmed drive plates, there

is no need to check setting height on drive

plates which are not shimmed.

1. Ensure bolt holes in crankshaft are clean and

dry. Fit original selective shim and hub aligner,

fit Allen bolts and tighten to 85 Nm (63 lbf.ft).

2. Fit drive plate assembly and clamp ring

ensuring that reference marks are aligned; fit

bolts and tighten to 45 Nm (33 lbf.ft).

CAUTION: If a new drive plate assembly is

being fitted, paint mark on plate must face

towards torque converter.

3. Check the setting height:

Drive plate setting height A = 8.08 to 8.20 mm

(0.32 to 0.33 in)

4. If setting height is not as specified, remove

clamp ring, drive plate assembly, hub aligner

and selective shim.