Inspection of Oil Pump during V8 Engine Overhaul for 35, 39 and 42 Models

ENGINE

OVERHAUL

29

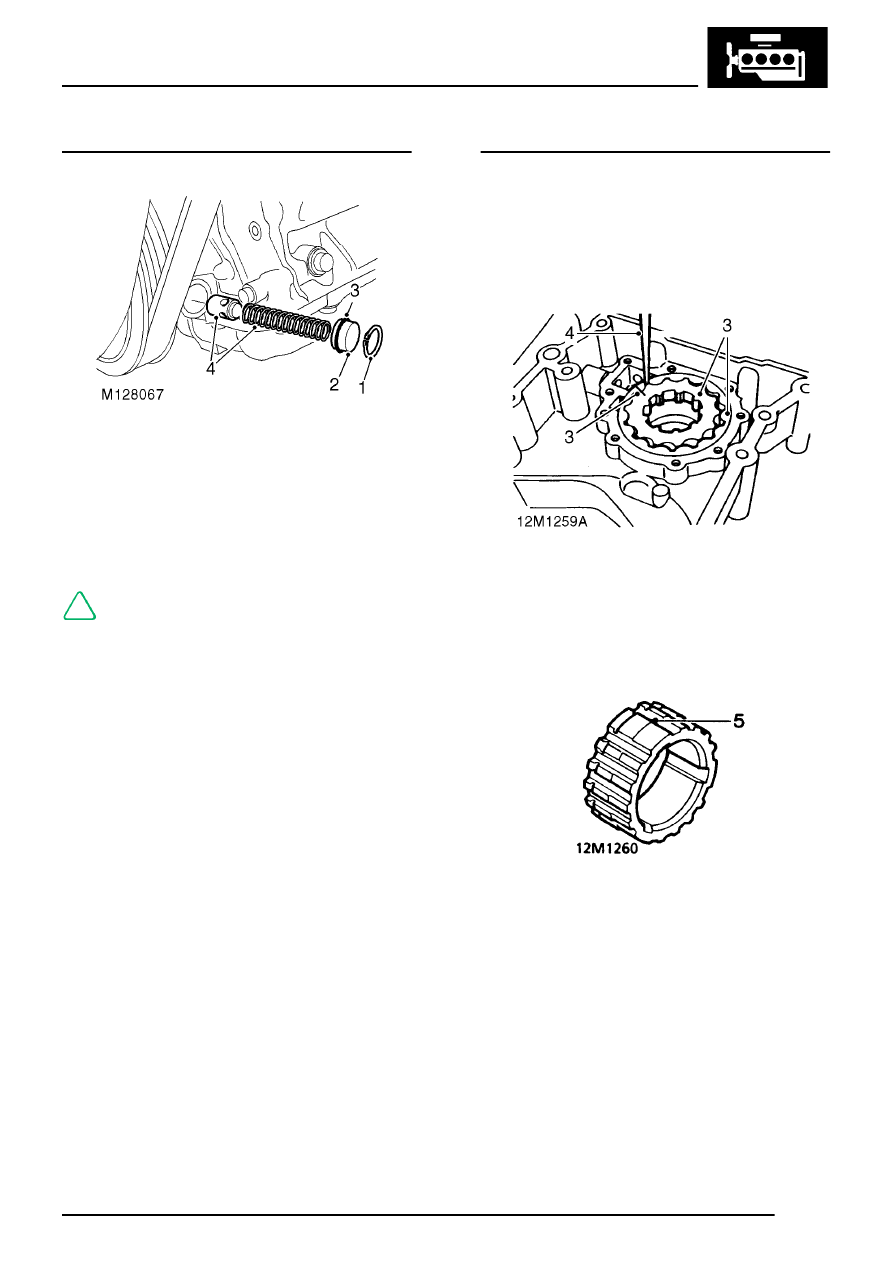

Oil pressure relief valve - remove

1. Remove circlip.

2. Remove relief valve plug.

3. Remove and discard ’O’ ring from plug.

4. Remove relief valve spring and piston.

5. Check piston and bore of relief valve in oil

pump body for scoring and corrosion.

NOTE: Light corrosion may be removed

using grade 600 emery cloth soaked in oil.

Oil pump - inspection

1. Thoroughly clean oil pump drive gear, cover

plate, rotors and housing. Remove all traces of

sealant from cover plate securing screws and

bolt - if fitted; ensure tapped holes in timing

cover are clean and dry.

2. Check mating surfaces of cover plate, rotors

and housing for scoring.

3. Assemble rotors and oil pump drive gear in

housing ensuring that reference marks are

aligned.

4. Using feeler gauges, check clearance between

teeth of inner and outer rotors:

Maximum clearance = 0.25 mm (0.01 in)

5. Remove oil pump drive gear, check depth of

any wear steps on gear teeth:

Wear step maximum depth = 0.15 mm (0.006

in)