V8 Engine 35 39 42 | Overhaul Pistons - Refit

ENGINE

OVERHAUL

39

Cylinder liner bore - inspection

1. Measure cylinder bore wear in two axis 40 to

50 mm (1.5 to 1.9 in) from top of bore:

Cylinder bore diameter - standard:

3.5 litre = 88.86 to 88.90 mm (3.498 to 3.50 in)

3.9 litre = 94.00 to 94.04 mm (3.700 to 3.702

in)

4.2 litre = 94.00 to 94.04 mm (3.700 to 3.702

in)

Maximum ovality = 0.013 mm (0.0005 in)

2. Compare cylinder bore diameter with piston

diameter and calculate piston to cylinder bore

clearance.

Piston to cylinder bore clearance = 0.015 to

0.045 mm (0.001 to 0.002 in)

CAUTION: The temperature of piston and

cylinder block must be the same to ensure

accurate measurement.

CAUTION: DO NOT attempt to de-glaze

cylinder bores.

Pistons - refit

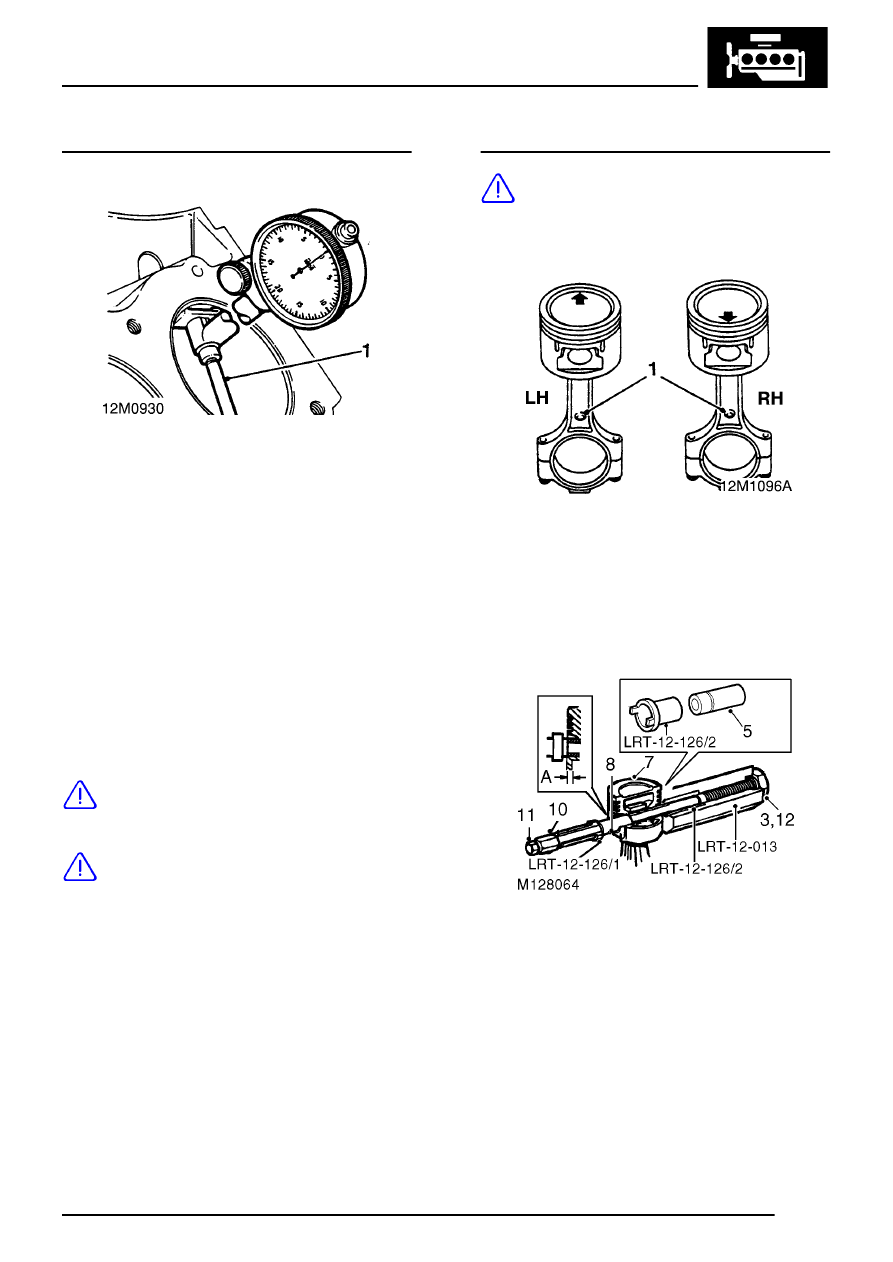

CAUTION: On later 4.2L engines the piston

has a 0.5 mm (0.02 in) offset gudgeon pin

which can be identified by an arrow mark

on the piston crown. This arrow MUST always

point to the front of the engine.

1. 4.2L engine only: Assemble pistons to

connecting rods with arrow on piston pointing

towards domed shaped bosses on connecting

rod for RH bank of cylinders, and arrow

pointing away from dome shaped bosses for

LH bank of cylinders.

2. Clamp hexagon body of LRT-12-013 in vice.

3. Screw large nut back until flush with end of

centre screw.

4. Locate remover/replacer adapter

LRT-12-126/2 with its long spigot inside bore

of hexagon body.

5. Fit parallel sleeve, part of tool LRT-12-013 with

grooved end towards open end of LRT-12-013

up to shoulder of centre screw.

6. Lubricate gudgeon pin and bores of connecting

rod and piston with graphited oil.