PB 150 V8-318 5.2L VIN T 2-BBL (1983)

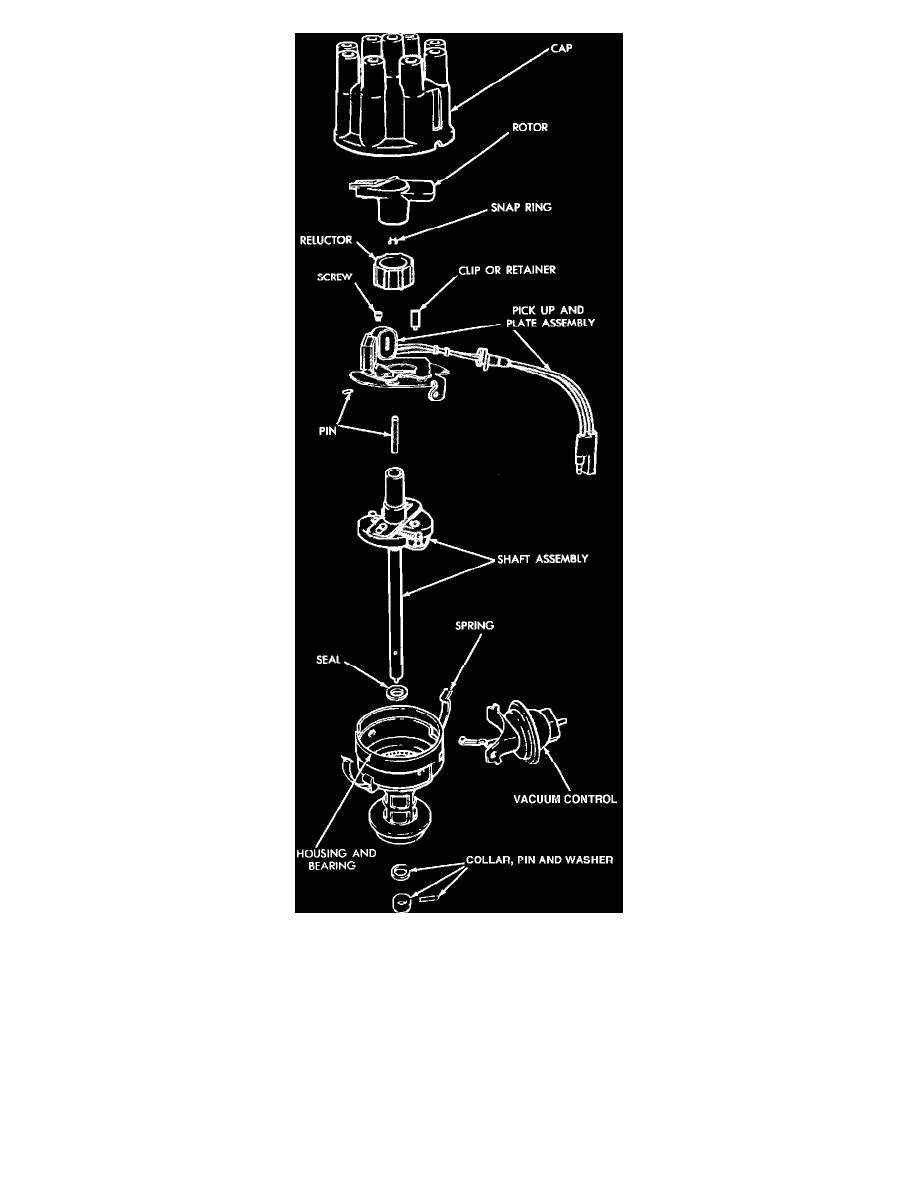

Fig. 14 Typical disassembled view of Chrysler electronic 8 cylinder distributor (Dual pickup distributor similar)

1.

Lubricate and test operation of governor weights. Inspect weight springs for distortion and bearing surfaces and pins for damage.

2.

Lubricate upper thrust washer and install onto shaft. Install shaft into housing.

3.

On eight cylinder units, install distributor shaft retainer and pin, Fig. 14.

4.

On all units, install lower plate, upper plate and pickup coil assembly.

5.

Attach vacuum advance unit to pickup plate, then install vacuum advance unit attaching screws and washers.

6.

Position reluctor keeper pin into place on reluctor sleeve, then slide reluctor down reluctor sleeve and press firmly into position. Install keeper pin.

7.

Lubricate felt pad located in top of reluctor sleeve with one drop of light engine oil, then install rotor.