Scamp L4-135 2.2L (1983)

Alignment: Service and Repair

Front Alignment

Prior to wheel alignment, ensure tires are at recommended pressure, are of equal size and have approximately the same wear pattern. Check front

wheel and tire assembly for radial runout and inspect lower ball joints and steering linkage for looseness. Check front and rear springs for sagging or

damage. Front suspension inspections should be performed on a level floor or alignment rack with fuel tank at capacity and vehicle free of luggage

and passenger compartment load.

Prior to each alignment reading, the vehicle should be bounced an equal number of times from the center of the bumper alternately, first from the rear,

then the front, releasing at bottom of down cycle.

CASTER

The caster angle on these vehicles cannot be adjusted.

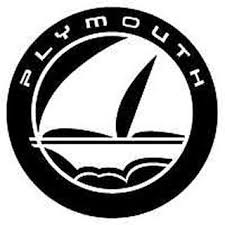

Fig. 2 Camber adjustment

CAMBER

To adjust camber, loosen the cam and through bolts. Rotate the upper cam bolt to move the top of the wheel in or out to achieve the specified camber

angle. Torque cam bolts to 45 ft. lbs., then advance bolts an additional 1/4 turn (90 degrees).

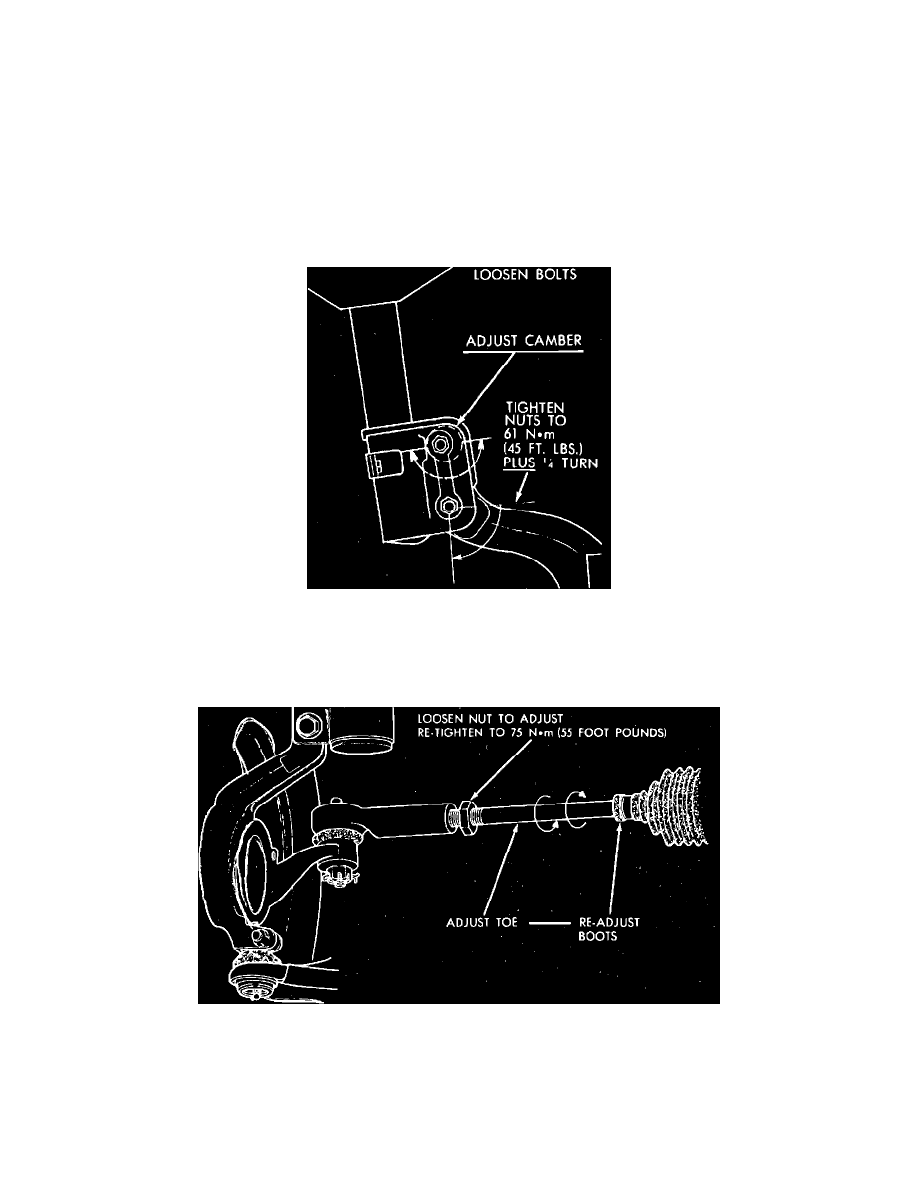

Fig. 3 Toe-in adjustment

TOE-IN

To adjust toe-in, center the steering wheel and hold in position with a suitable tool. Loosen the tie rod lock nuts and rotate the rod, to adjust toe-in to

specifications. Use care not to twist the steering gear rubber boots. Torque the tie rod lock nuts to 55 ft. lbs. (75 Nm). Adjust position of steering gear

rubber boots. Remove steering wheel holding tool.