Leon Mk1

Note!

Note!

|

|

|

|

|

|

|

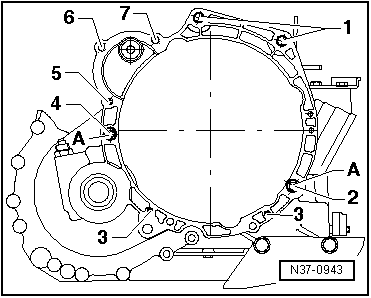

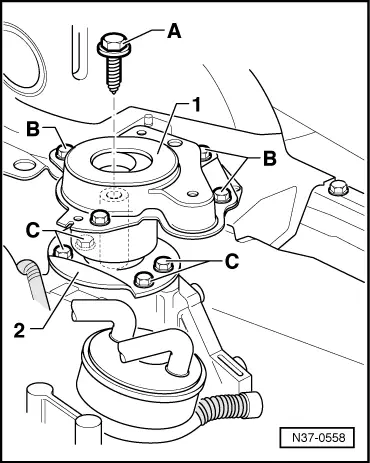

| Position | Bolt | Amount | Tightening torque (Nm) |

| 1 | M12×65 | 2 | 80 |

| 2 | M10×75 | 1 | 45 |

| 3 | M7×12 | 2 | 15 |

| 4 | M12×70 | 1 | 80 |

| 5 | M8×35 | 1 | 25 |

| 6 | M8×35 | 1 | 25 |

| 7 | M8×35 | 1 | 25 |

|

|

|

|

|

|

|

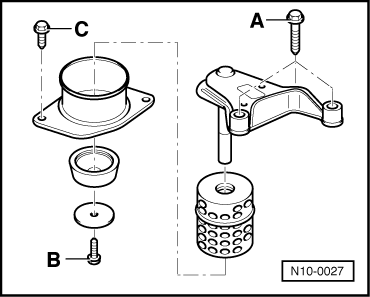

| Torque converter to the flywheel | 60 Nm | |

| Always renew the bolts | ||

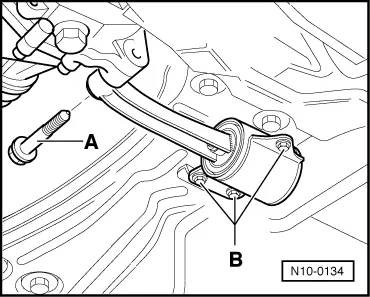

| Driveshaft to flange connection | 45 Nm | |

| Always renew the bolts | ||

| Gearbox to engine bolt M12 | 80 Nm | |

| Gearbox to engine bolt M10 | 60 Nm | |

| Gearbox oil sump protective plate. | 15 Nm | |