| t

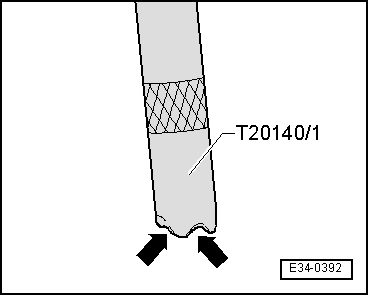

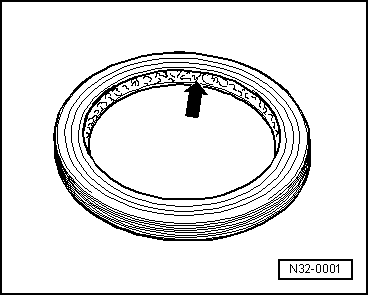

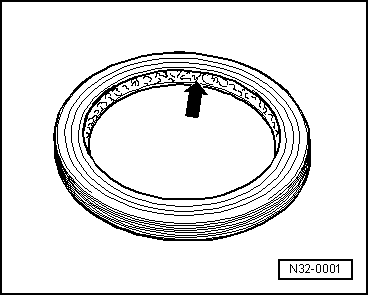

| On fitting split pins, the expansion groove should be facing the direction of power transmission, as seen in the illustration |

| t

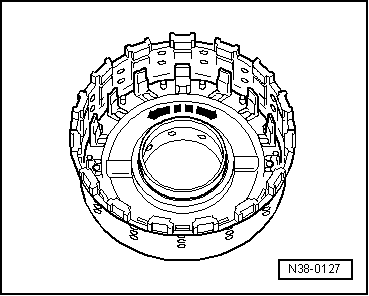

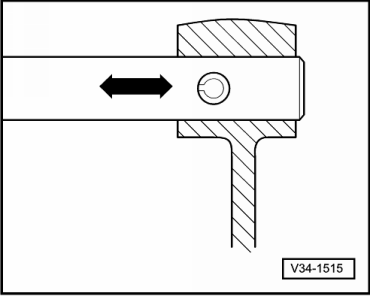

| Always loosen and tighten nuts and bolts on covers and casing in diagonal sequence |

| t

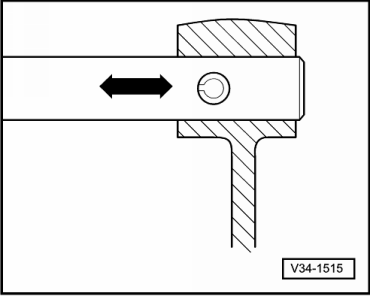

| For delicate parts, e.g. the slide box , always loosen and tighten the bolts in stages and in diagonal sequence |

| t

| Tightening torques are specified for nuts and bolts without lubrication |

| t

| Always replace any self-locking nuts and bolts |

| t

| Bolts with torque and stretch specifications must always be renewed |

| t

| If the bolt threads have remains of locking paste, clean with a wire brush. Then insert the bolts with -AMV 185 100 A1- |

| t

| The bolts and nuts of all threaded joints will be waxed when fitted (if necessary) |

| t

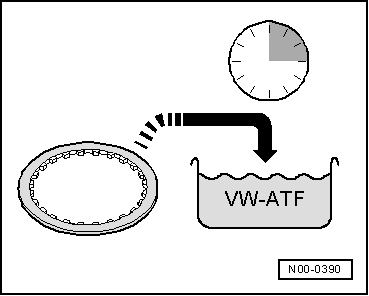

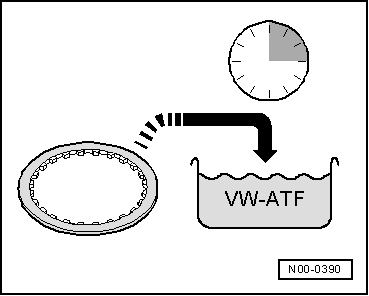

| Partially lubricate all gearbox bearings with ATF fluid before fitting |

| t

| Fit new roller bearings as supplied, without lubrication, especially the conical bearings |

| t

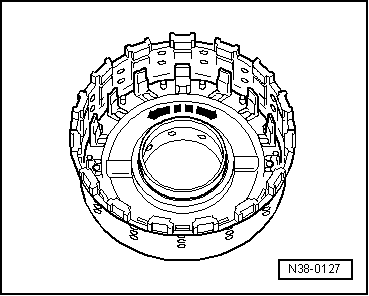

| Place the axial needle bearings in their correct position → Chapter |

| t

| Bearings corresponding to the same shaft will be all replaced together, especially conical bearings. If possible, use parts from the same manufacturer |

| t

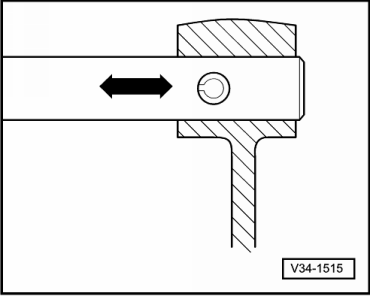

| Do not mix up the inner and outer rings of the same size bearings. The bearings come in matched pairs |

| t

| Heat the inner roller bearing ring to 100°C before press fitting |

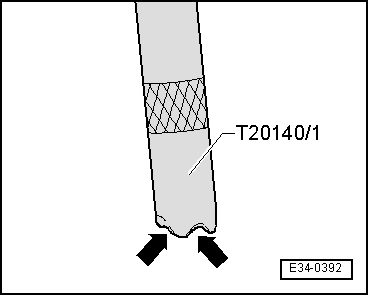

| Remove the outer rings of the roller bearings or the bearing bushes as follows: |

| –

| Measure (if possible) the internal diameter of the external ring of the roller bearing or the bearing bush. |

| –

| Select the correct clamp from the tool set according to: |

| If the diameter measured is less than 30 mm: |

| –

| Fit the plunger for small clamps/10 and the correct clamp for internal diameters. |

| If the diameter measured is more than 30 mm: |

| –

| Fit the plunger/28 and clamp /29 and the correct claws for the internal diameter. |

| –

| Screw nut /5 and washer on the plunger. |

| –

| Place the tool on the outer ring of the roller bearing or the bearing bush and fit the threaded legs so that they are firmly secured. |

Note! |

|

|

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!