Leon Mk1

| Differential: dismounting and assembling |

| t | The differential must be adjusted whenever the tapered roller bearings are replaced. Consult the Adjustments Chart → Chapter. |

| t | The tapered roller bearings must always be replaced together. |

| t | The tapered roller bearings and their corresponding outer tracks come in pairs. Do not mix them up or exchange them with other bearings. |

| Assembly chart |

| 1 - | Gearbox casing |

| 2 - | Bolt |

| 3 - | Differential box |

| q | In the event of replacement, consult the Adjustments Chart → Chapter. |

| 4 - | Crown for the riveted differential |

| q | Factory riveted |

| q | Assembly with bolts → Chapter |

| q | In the event of replacement, the crown of the differential and the secondary shaft must be replaced together. |

| q | Dismounting and assembly → Chapter, Crown of the differential: dismounting and assembling |

| 5 - | Plate washer |

| 6 - | Nut, 70 Nm |

| 7 - | Adjustment washer |

| q | Determine the thickness → |

| 8 - | Outer track, tapered roller bearing |

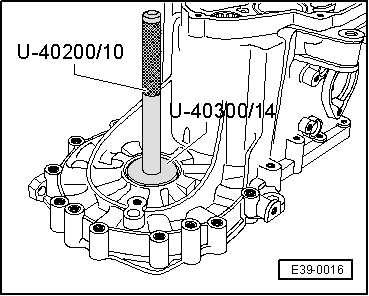

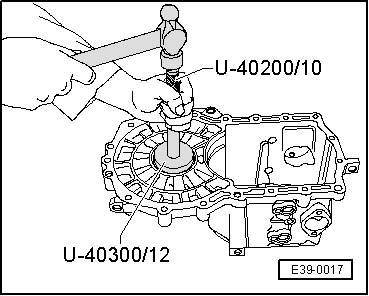

| q | Dismount → Fig. |

| q | Assemble → Fig. |

| 9 - | Tapered roller bearing |

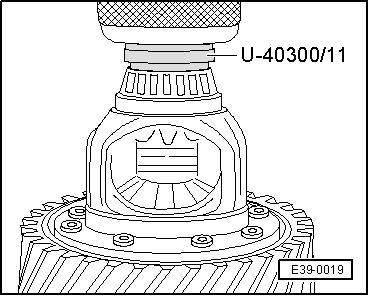

| q | Dismount → Fig. |

| q | Assemble → Fig. |

| 10 - | Differential unit |

| q | In the event of replacement, the crown of the differential and the secondary shaft must be replaced together. Consult the Adjustments Chart → Chapter. |

| q | Factory riveted crown. |

| q | Drilling of the rivets and assembly with bolts → Chapter |

| 11 - | Pinion for working the speedometer |

| q | Dismount it by levering with a flat screwdriver. |

| q | Assembly: fit it in up to the top in the differential box before assembling the tapered roller bearing → Item. |

| 12 - | Tapered roller bearing |

| q | Dismount → Fig. |

| q | Assemble → Fig. |

| 13 - | Outer track, tapered roller bearing |

| q | Dismount → Fig. |

| q | Assemble → Fig. |

| 14 - | Clutch casing |

| 15 - | Bush |

| q | Retainer for the coupling flange |

| q | Dismount and assemble → Chapter |

| 16 - | Retainer for the coupling flange |

| q | Replace → Chapter |

| 17 - | Bolt, 25 Nm |

| q | Screw in with the threaded part for attaching the coupling flanges → Item. |

| 18 - | Coupling flanges |

| q | Dismount and assemble → Chapter |

| 19 - | Spring for coupling flange |

| q | Assemble it behind the coupling flange. |

| 20 - | Front washer |

| q | Position for assembly: Collar facing towards the spring, core facing towards the tapered ring. |

| 21 - | Tapered ring |

| q | With trimmings for fitting the front washer |

| q | Position for assembly: tapered side facing towards the differential box. |

| 22 - | Safety ring |

| q | Keeps the tapered ring, the washer and the spring for the coupling flange in position when the latter is dismounted. |

| 23 - | Set of friction washers |

| q | Coat them with gearbox oil before assembling them. |

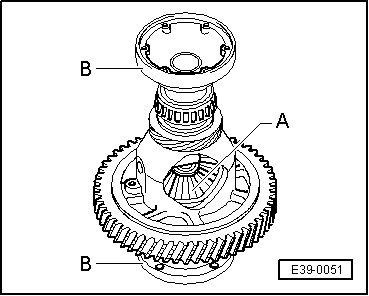

| 24 - | Differential side gear |

| q | Assemble → Fig. |

| 25 - | Threaded part for attaching the coupling flanges |

| q | Assemble → Fig. |

| 26 - | Axle for satellites |

| q | Dismount it by striking with a punch. |

| 27 - | Elastic linchpin |

| q | Dismount it by striking with a suitable punch. |

| q | Assemble ⇒ Fit it up to the stop. |

| 28 - | Satellite |

| q | Assemble → Fig. |

| 29 - | Differential side gear |

| q | Assemble → Fig. |

| Special tools and workshop equipment required |

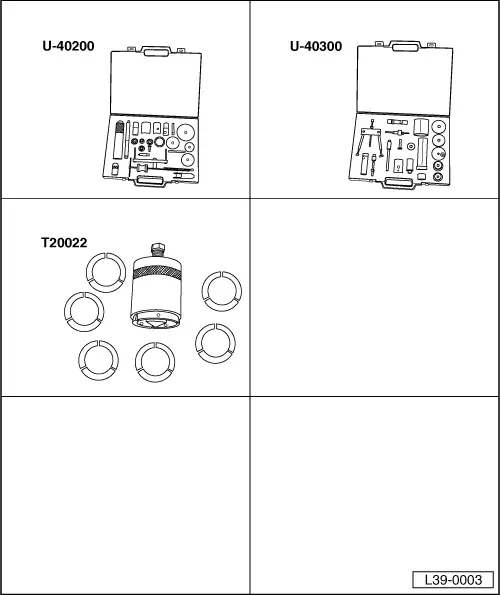

| t | Case of tools for repairing gearboxes -U-40200- |

| t | Case of tools for repairing gearboxes -U-40300- |

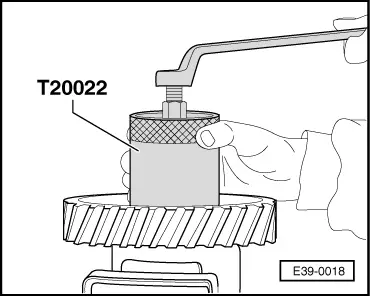

| t | Pincer extractor tool with grippers -T20022- |

Note!

Note!

|

|

|

|

Note!

Note!

|

|

|

|