| t

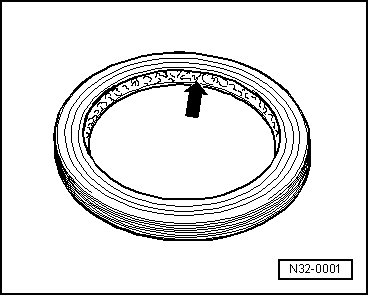

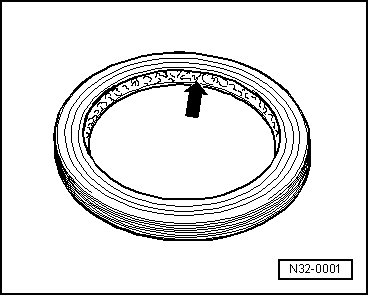

| The safety rings must fit perfectly into the bottom of the insertion slot. |

| t

| Always replace the elastic guide pins. |

| t

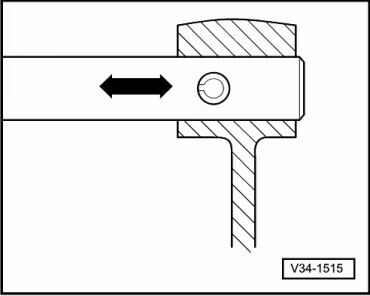

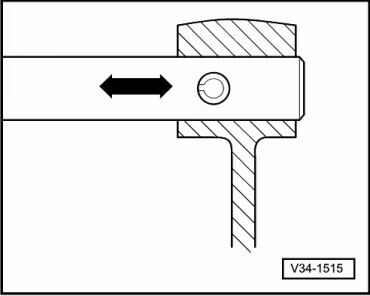

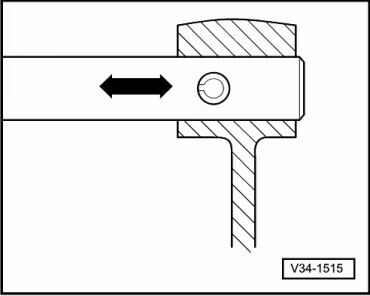

| When assembling the plastic guide pins, their slot must be positioned longitudinally with respect to the direction of the drive, as shown in the figure. |

| t

| Always loosen and tighten the bolts and nuts in a cross-shape for attaching covers and casings. |

| t

| With delicate parts, such as, for example, the clutch press, do not tilt them and carry out the operation gradually. |

| t

| Self-locking bolts and nuts must always be replaced |

| t

| When new conical bearings are assembled, they shall be assembled as they arrive, without greasing. |

| t

| The needle bearings must be assembled with the thickest side of the plate facing towards the assembly axle-tool. |

| t

| All the bearings for the gearbox must be put into place slightly oiled for the gears. Take special care when oiling them for the friction torque measurements. |

| t

| The bearings belonging to the same shaft must be replaced together. Use parts from the same manufacturer as far as possible. |

| t

| For putting the bearings into place, they must first be heated to a temperature of approximately 100 °C. Use the electrical blower -SAT 1416- and the digital thermometer -SAT 4002- to check the temperature. |

| t

| Do not confuse or exchange the outer tracks for the bearings of the same size; the bearings come in pairs. |

| t

| Before assembling the adjustment washers, their thickness must be checked by measuring them with a micrometer at several points on their surface |

| t

| The presence of washers with different tolerances allows the precise thickness of the washer that is needed to be achieved. |

| t

| The washers must not have rough edges or defects. |

| t

| Assemble only adjustment washers that are in perfect condition. |

| t

| Do not mix synchronising rings together with different gears. If they must be used again, place them in the same gear as before. |

| t

| Check them for wear and replace them if necessary. |

| t

| For their assembly, cover them with oil for gears. |

| t

| Before assembling them, clean them very carefully. They must first be heated to a temperature of approximately 100 °C. Use the electrical blower -SAT 1416- and the digital thermometer -SAT 4002- to check the temperature. |

| t

| New gearbox code letters have been introduced, with a new mineral gear oil -API GL4 SAE 75W- according to standard TL 726 /Y (hypoid oil) This type of oil must only be used in the specified gearboxes and never in those that used the former oil -API GL4 SAE 75W90- according to standard TL 521 57 (synthetic oil) |

| t

| Oils with different denominations and standards should never be mixed as this modifies the properties of the lubricants |

|

|

|