| Before fitting the differential crown, consult the section. Code letters, assignement of groups, ratios, filling amounts → Chapter. |

| –

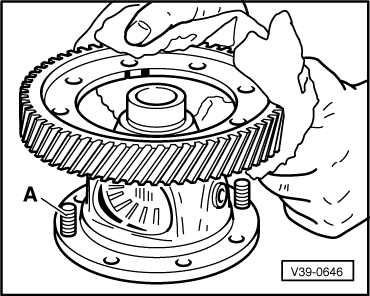

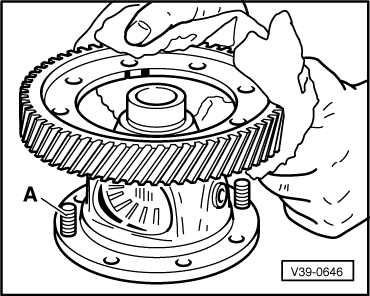

| Clean the contact surfaces of the crown wheel and differential casing thoroughly. Use a wire brush and a scraper. Do not use emery cloth or sandpaper. The contact surfaces must be totally clean and freee from oil and grease. |

Note! | t

| To fit the crown correctly onto the differential casing work rapidly without interruptions fitting it to the limit |

| t

| If both components lock or jam on fitting, stop the assembly process and start again |

|

|

|

Note!

Note!

Note!

Note!