Leon Mk1

| Input shaft: dismantling and assembling |

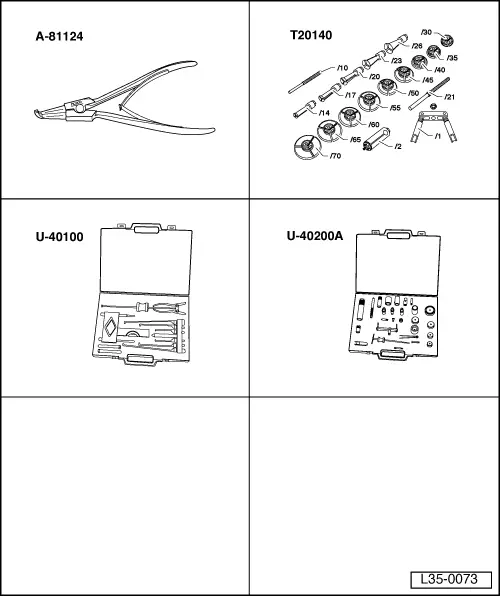

| Special tools and workshop equipment required |

| t | Pliers -A-81124- |

| t | Kit -T20140- |

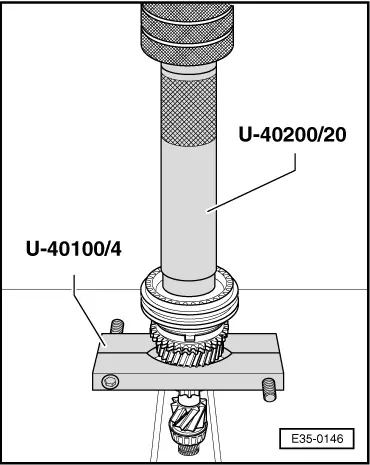

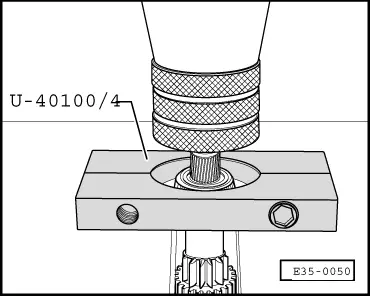

| t | Kit -U-40100- |

| t | Kit -U-40200 A- |

Note!

Note!| t | Whenever new gears are fitted consult the technical data → Chapter. |

| t | The input shaft must be adjusted whenever elements have been replaced which could affect the position of the roller bearings. Refer to Adjustment chart → Chapter. |

| 1 - | M8 Torx screw, 40 Nm |

| 2 - | Plate spring |

| 3 - | 5th gear |

| q | Removing and installing → Chapter, assembly sequence |

| 4 - | Washer |

| q | Always 1 mm thick |

| q | Fitted to gearboxes manufactured from 07.97, except those bearing the letters DQW |

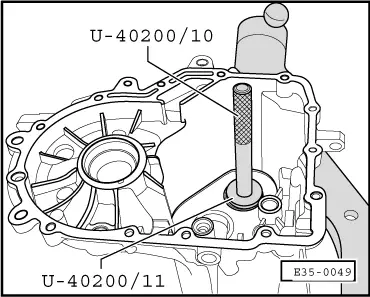

| 5 - | Outer track, roller bearing |

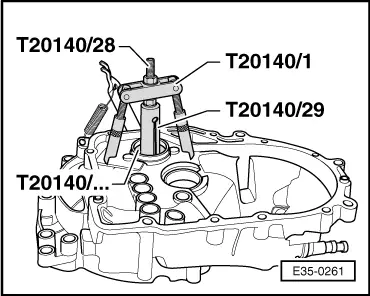

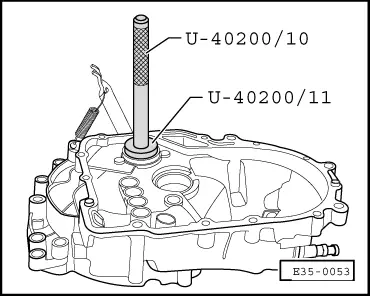

| q | Remove → Fig. |

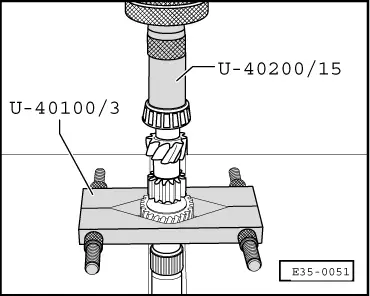

| q | Fitting → Fig. |

| 6 - | Roller bearings |

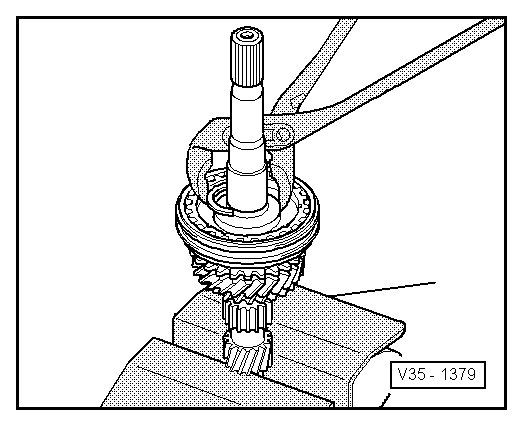

| q | Remove → Fig. |

| q | Fitting → Fig. |

| 7 - | Gearbox casing |

| q | In gearboxes manufactured from 07.97, except those bearing the letters DQW, and due to washer → Item the outer track of the roller bearing fits 1 mm lower |

| 8 - | Input shaft |

| q | Adjust → Chapter |

| 9 - | Needle bearing |

| q | Lubricate before fitting |

| 10 - | Sliding 3rd gear |

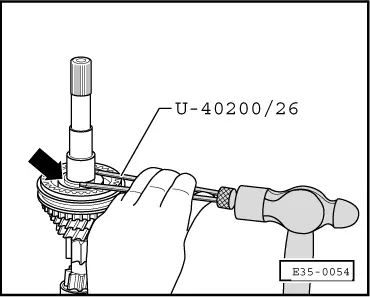

| q | Remove → Fig. |

| q | Fitting → Fig. |

| q | It is fitted together with the sliding sleeve and the 3rd and 4th gear syncromesh hub |

| 11 - | Syncromesh ring 3rd gear |

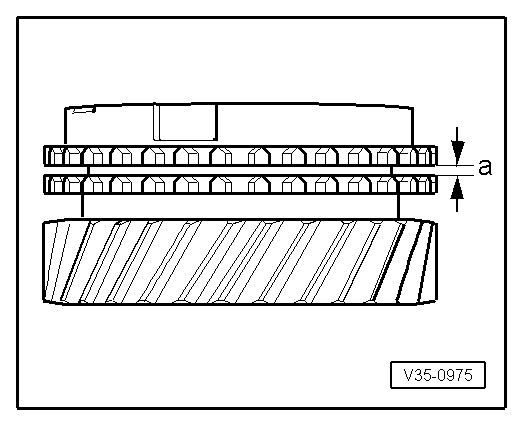

| q | Checking for wear → Fig. |

| 12 - | Safety ring |

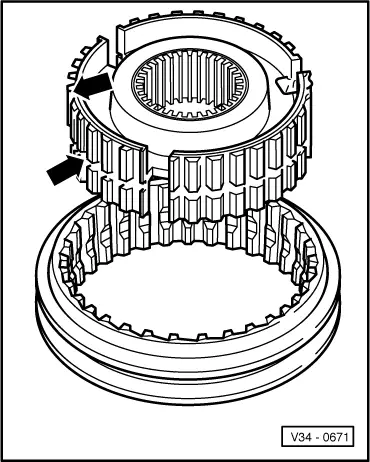

| q | Separation → Fig. |

| q | Location → Fig. |

| 13 - | 3rd and 4th syncromesh assembly |

| q | They are matching pairs |

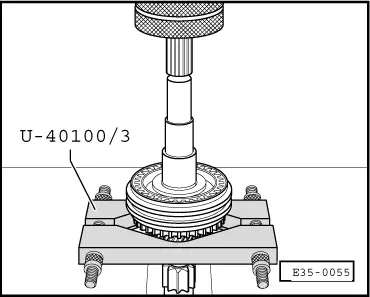

| q | Separation → Fig. |

| q | Assemble → Fig. |

| q | Fitting the input shaft → Fig. |

| 14 - | Safety ring |

| q | Separation → Fig. |

| q | Location → Fig. |

| 15 - | Syncromesh ring 4th gear |

| q | Checking for wear → Fig. |

| 16 - | 4th gear |

| 17 - | Needle bearing |

| q | Lubricate before fitting |

| 18 - | Stop washer |

| 19 - | Roller bearings |

| q | Can be removed without tools |

| 20 - | Shim |

| q | For the input shaft |

| q | Determine thickness → Chapter |

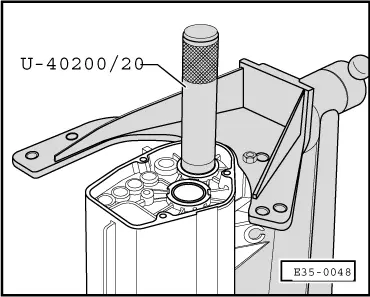

| 21 - | Outer track, roller bearing |

| q | Remove → Fig. |

| q | Fitting → Fig. |

| 22 - | Clutch housing |

| 23 - | Spring |

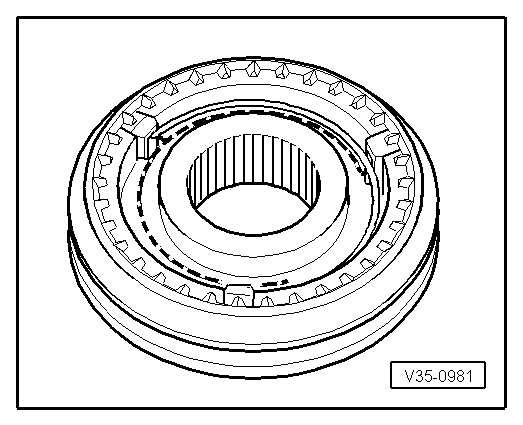

| q | Fitting position → Fig. |

| 24 - | Locking keys |

| 25 - | Sliding sleeve |

| 26 - | Syncromesh hub |

| q | Identiifcation and assembly of hub → Fig. |

| 27 - | Spring |

| q | Fitting position → Fig. |

Note!

Note!

|

|

Note!

Note!

|

|

|

|

|

|

|

|

|

|

|

|

Note!

Note!

|

|

|

|

| Syncromesh ring | Measurement “a” on a new syncromesh | Wear limit |

| 3rd and 4th gears | 1.1 to 1.7 mm | 0.5 mm |

|

|

|

|

|

|

Caution

Caution