Leon Mk1

| Differential: adjustment |

| Special tools and workshop equipment required |

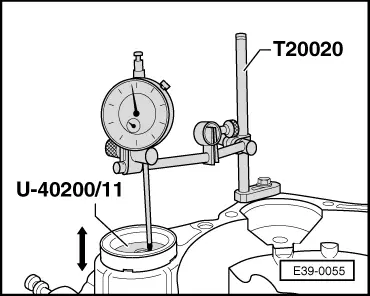

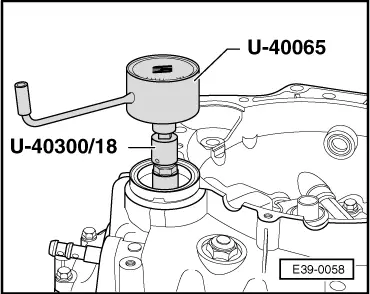

| t | Multi-purpose stand for the comparator -T20020- |

| t | Turning torque tester -U-40065- |

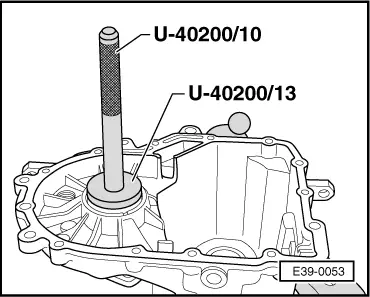

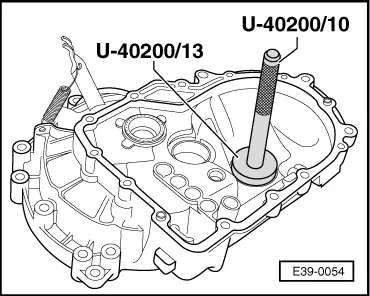

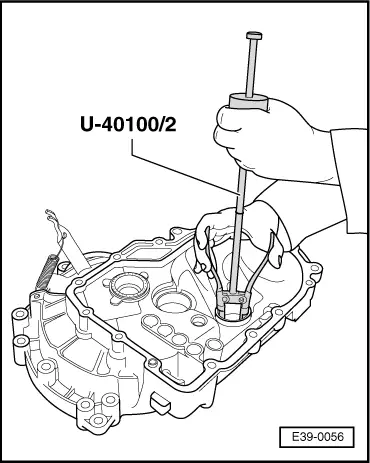

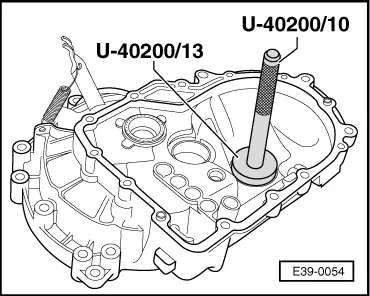

| t | Case for extractor tools for gearboxes -U-40100- |

| t | Case for repairing gearboxes -U-40200- |

| t | Replacement parts repair case -U-40300- |

|

Note!

Note!

|

|

Note!

Note!

|

|

Note!

Note!

|

|

| Reading obtained with the comparator | 1,5 mm |

| Set value | 0,3 mm |

| Thickness of the S2 adjustment washer | 1,8 mm |

|

| Thickness (mm) | Replacement part Nº |

| 1,00 1,40 1,45 | 084 409 383 AE 084 409 383 AF 084 409 383 AG |

| 1,50 1,55 1,60 | 084 409 383 AH 084 409 383 AJ 084 409 383 AK |

| 1,65 1,70 1,75 | 084 409 383 AL 084 409 383 AM 084 409 383 AN |

| 1,80 1,85 1,90 | 084 409 383 AP 084 409 383 AQ 084 409 383 AR |

| 1,95 2,00 2,05 | 084 409 383 AS 084 409 383 AT 084 409 383 BA |

| 2,10 2,15 2,20 | 084 409 383 BB 084 409 383 BC 084 409 383 BD |

| 2,25 2,30 2,35 | 084 409 383 BE 084 409 383 BF 084 409 383 BG |

| 2,40 | 084 409 383 BH |

|

|

|

|

|

|

|