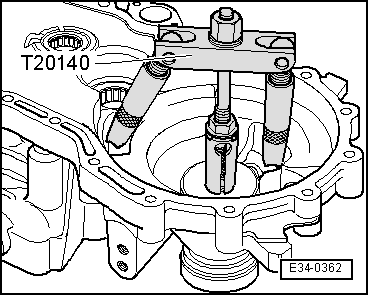

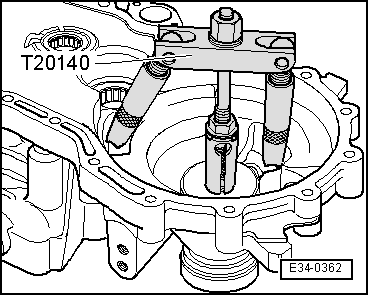

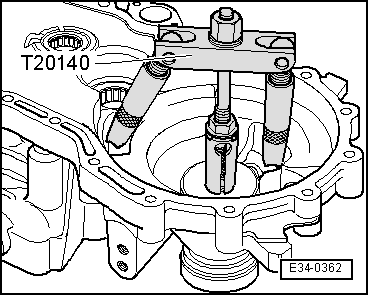

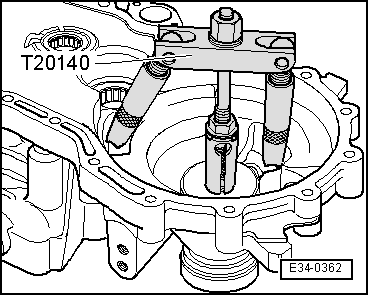

| Release the outer ring of the conical roller bearing bush from the gearbox casing |

Note | t

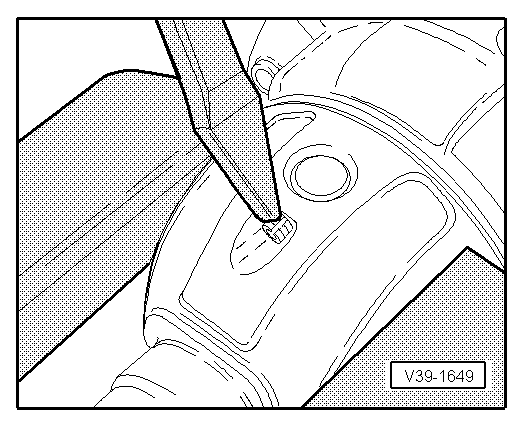

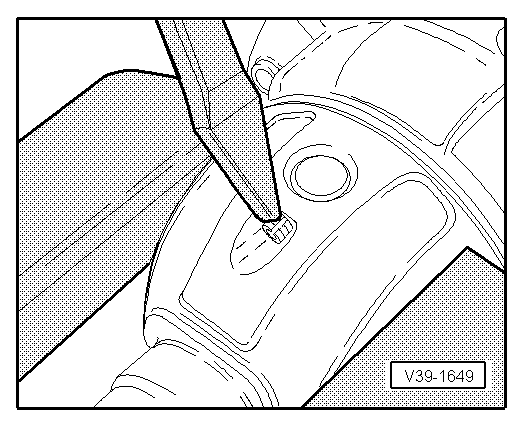

| Once the outer bearing ring has been removed, check if the washer is damaged; if necessary replace it. Do not change the thickness of the washer, this may lead to serious damage (always 1 mm). |

| t

| When replacing the secondary shaft bearing, always adjust the friction couple of the differential box. |

| –

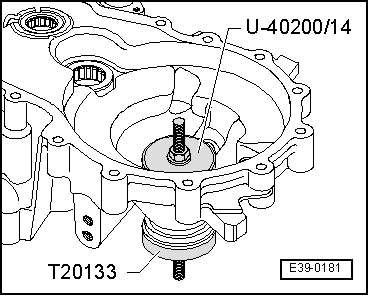

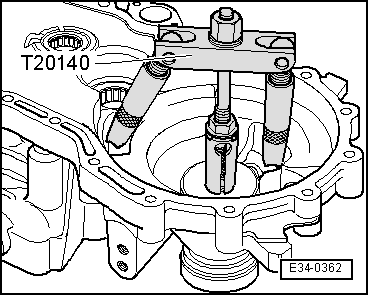

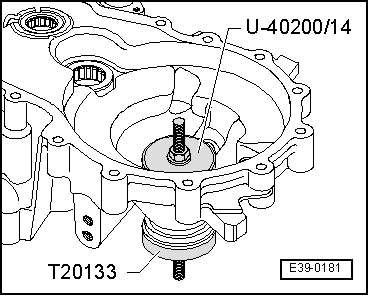

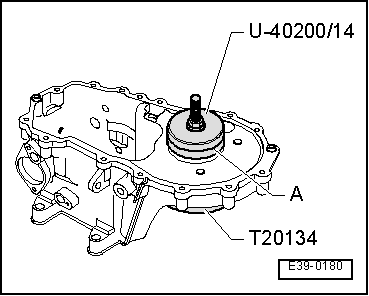

| Check whether a shim S1 has to be placed under the outer race → Fig.. |

| Continue for gearboxes up to manufacturer week 49.2006 |

| –

| First fit the S1 shim, always 1 mm in thickness, underneath the outer ring. |

| Continued for all gearboxes |

| –

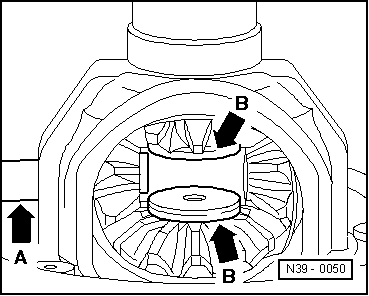

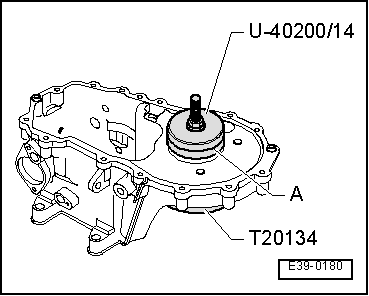

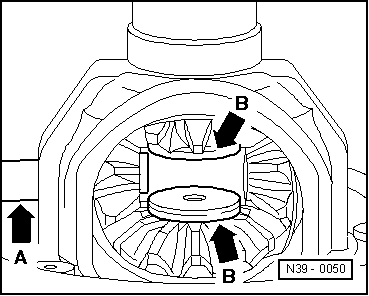

| Support the gearbox housing by placing the thrust piece -T20134- directly below bearing support. |

Note | t

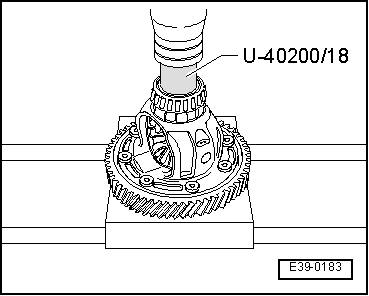

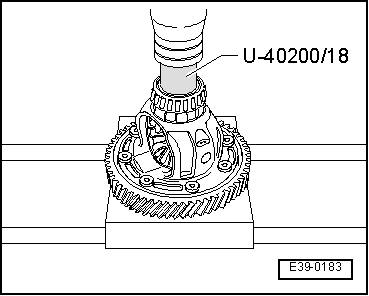

| Always replace the conical roller bearings when the differential is removed. |

| t

| The roller bearings and their corresponding outer tracks are matched pairs. They must not be confused or interchanged. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note