| –

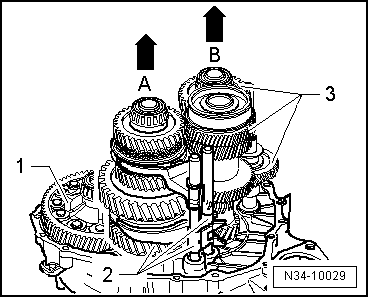

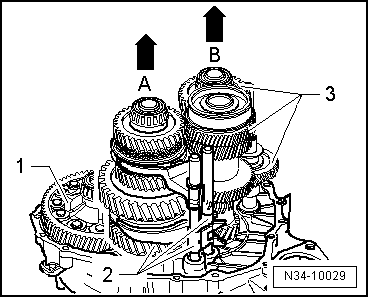

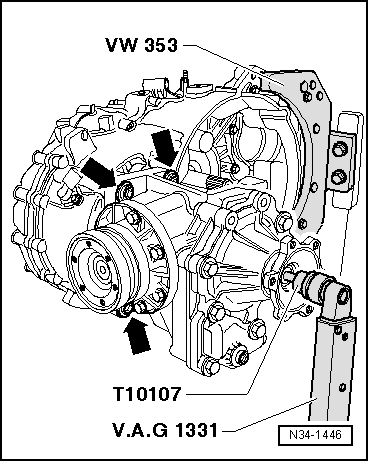

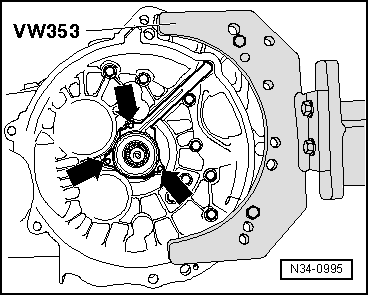

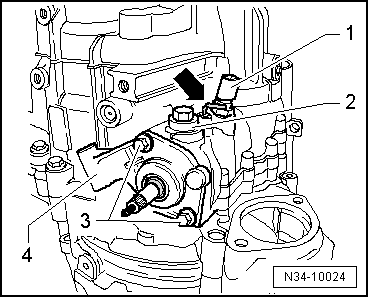

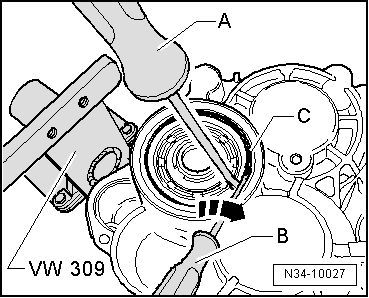

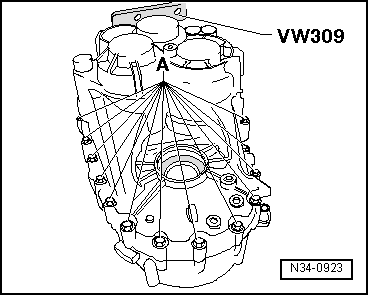

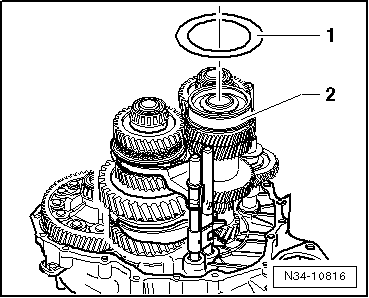

| With left hand, raise differential -1-. With right hand, lift output shaft for 1st to 4th gear together with selector rods -2--arrow A-. |

| –

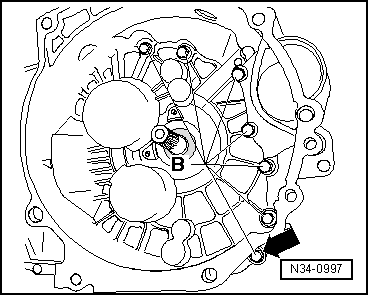

| At same time, second mechanic lifts input shaft, reverse shaft and output shaft for reverse, 5th and 6th gears -3- together with selector rods out of clutch housing -arrow B-. |

Note! | After shafts are lifted, differential may be set back in clutch housing if desired. |

| –

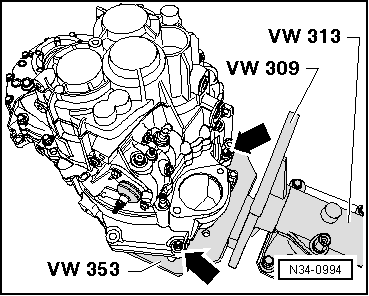

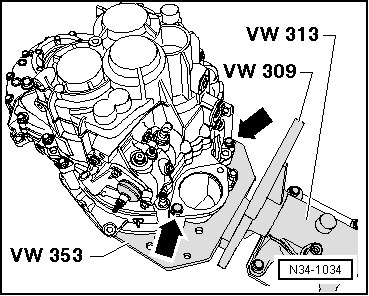

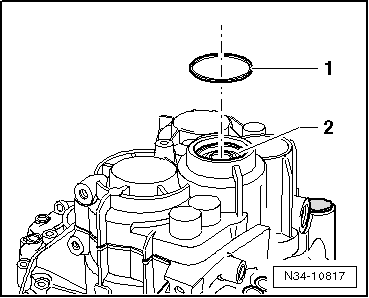

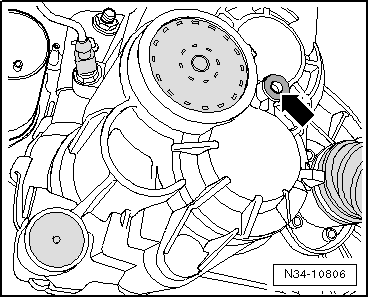

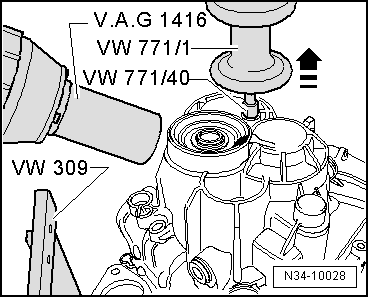

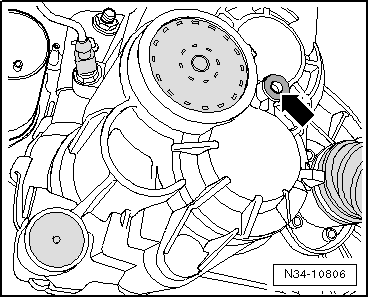

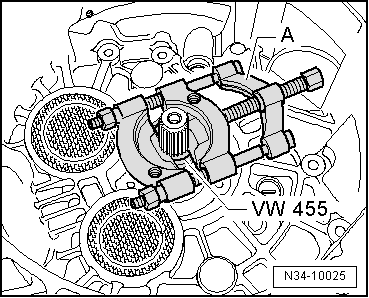

| Drive out input shaft oil seal using sleeve -30-21-. |

Note! | Always renew deep groove ball bearing on input shaft → Item. |

|

|

|

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note! Note!

Note!