Leon Mk1

|

|

|

|

|

|

|

|

|

|

|

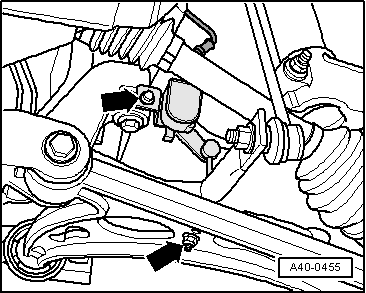

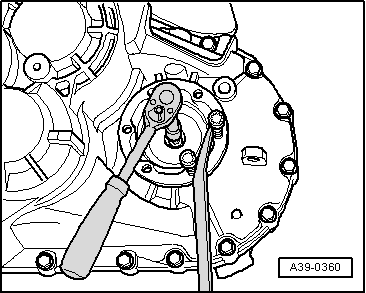

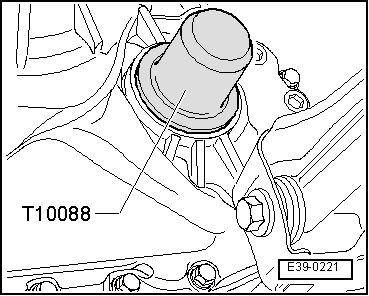

| Component | Nm | |

| Flanged shaft to differential | 25 → Item | |

|

|

|

|

|

|

|

|

|

|

|

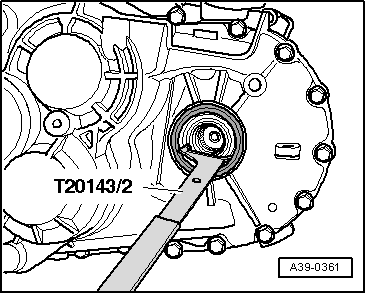

| Component | Nm | |

| Flanged shaft to differential | 25 → Item | |