| To remove shafts from clutch housing, a second mechanic is required. |

| –

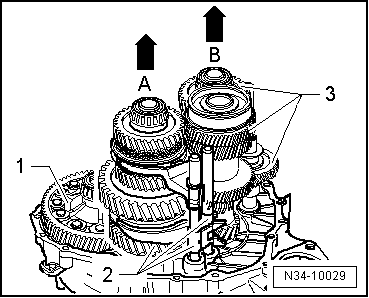

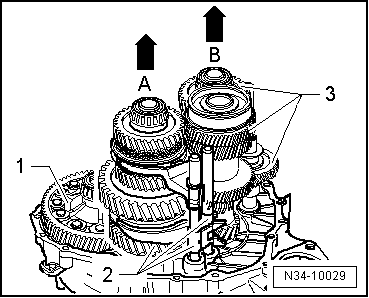

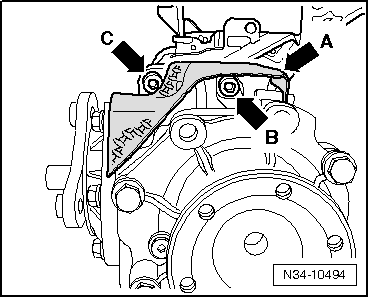

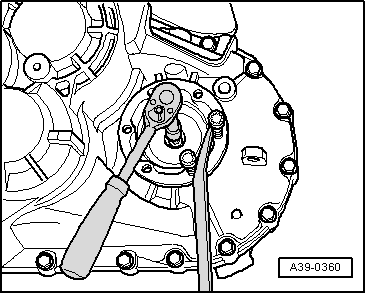

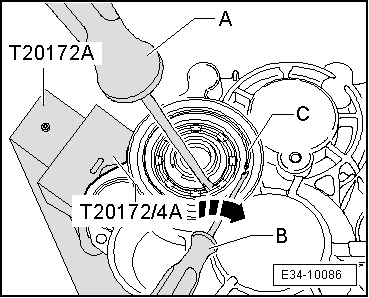

| Lift the differential -1- and simultaneously lift the secondary shaft of the 1st to 4th gear with the selector rods -2-, -arrow A-. |

| –

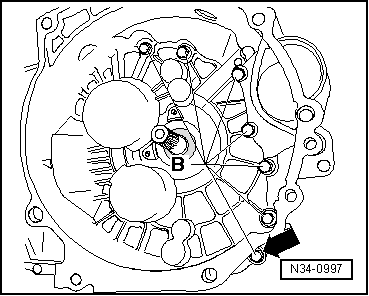

| At the same time, the second mechanic must remove the primary, inverter and secondary shaft of the 5th / 6th gears -3-, along with the control rods, out of the clutch housing -arrow B-. |

Note | In case of doubt, the differential may rest on the clutch housing after lifting the shafts. |

| –

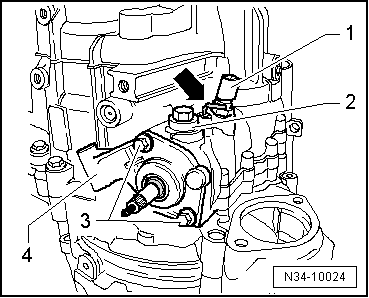

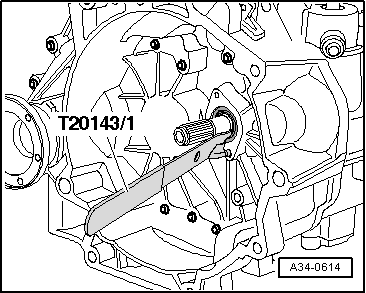

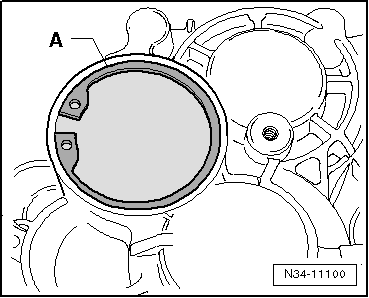

| Removing the input shaft oil seal → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note