Note | t

| Refer to procedure „Removing gearbox“ for required special tools → Chapter. |

| t

| Always renew self locking nuts and bolts |

| t

| Renew bolts which must be tightened further to a torque angle. |

| t

| All cable ties which were opened or cut during removal must be renewed at the same points. |

| t

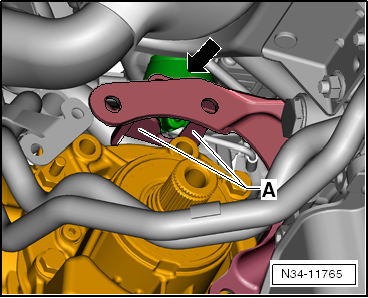

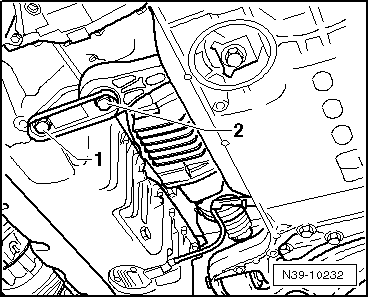

| Clean input shaft splines and, on used clutch plate, hub splines. Remove corrosion and apply only a very thin coat of clutch plate spline grease -G 000 100- to splines. Then move clutch plate to and fro on input shaft until hub moves freely on shaft. Remove excessive grease. |

| –

| All threaded holes into which self-locking bolts are to be screwed must be cleaned of residual locking fluid carefully with a thread tap. |

| –

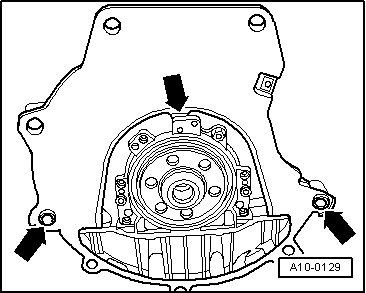

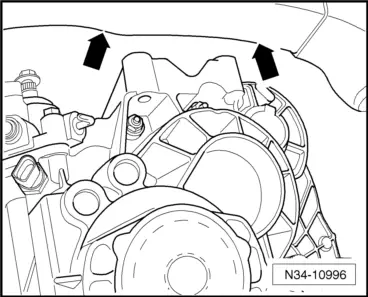

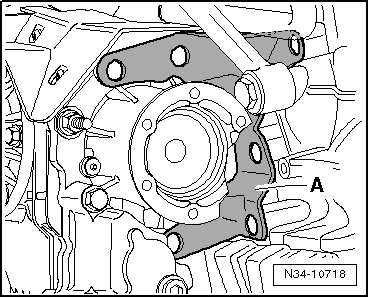

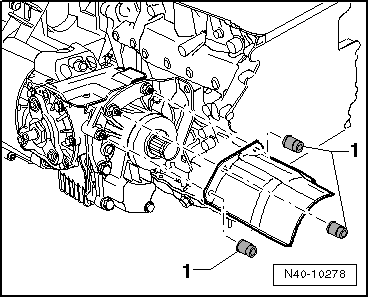

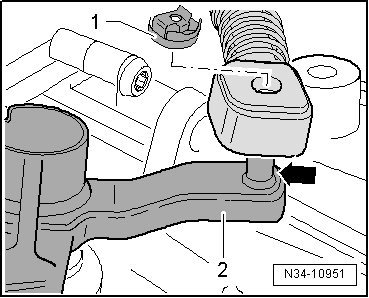

| Check if the centring sleeves are installed in the engine for the purpose of centring the engine with the gearbox and insert these if they are not installed. |

| If dowel sleeves are not fitted, difficulties shifting gears, clutch problems and possible noises from the gearbox (rattling of gears which are not engaged) could occur. |

|

|

|

Note

Note

Note

Note

Note

Note

WARNING

WARNING