Leon Mk1

|

| Special tools and workshop equipment required |

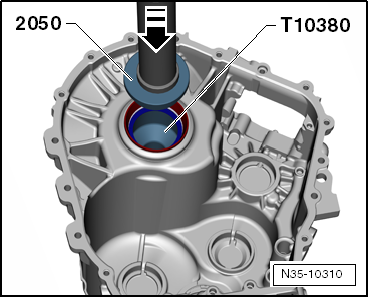

| t | pressure tool -2050- |

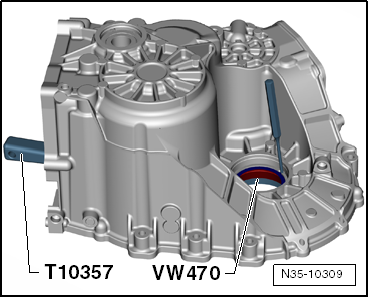

| t | Wedge -T10357- |

| t | Mounting part -T10380- |

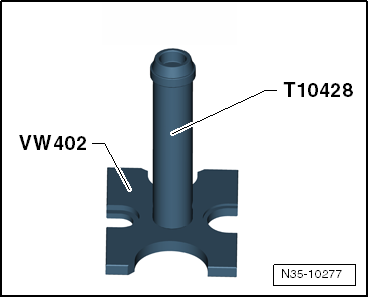

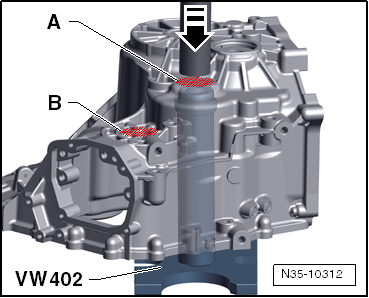

| t | pressure tool -T10428- |

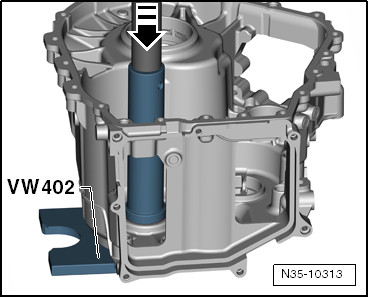

| t | Tensioning tool -VW 402- |

| t | Remove the sleeve -VW 470- |

| t | pressure tool -VW 473- |

| t | Internal puller (ø 45 to 58 mm) -KUKKO 21/7- |

| 1 - | Gearbox |

| q | With oil guide → Fig. |

| 2 - | Retainer washer |

| q | Smooth side faces outwards |

| 3 - | Differential shim |

| q | Determining thickness → Chapter |

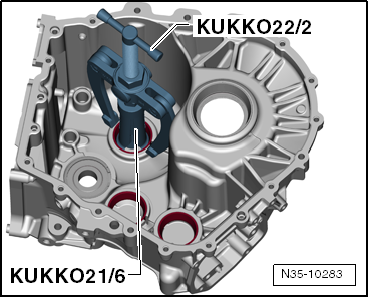

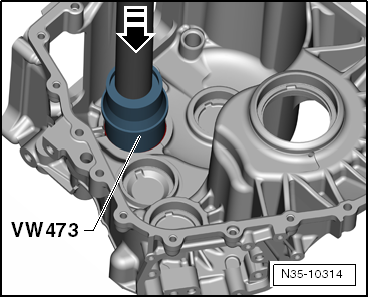

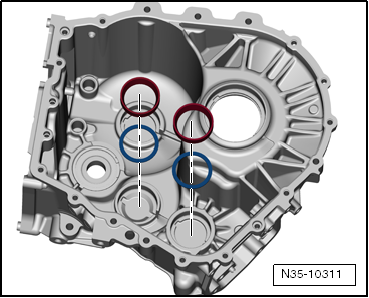

| 4 - | Differential bearing race |

| q | Pressing out → Fig. |

| q | Pressing on → Fig. |

| 5 - | Output shaft shim 3 |

| q | Determining thickness → Chapter |

| 6 - | Output shaft bearing race 3 |

| q | Pulling out → Fig. |

| q | Preparing for pressing in → Fig. |

| q | Pressing on → Fig. |

| 7 - | Output shaft shim 2 |

| q | Determining thickness → Chapter |

| 8 - | Output shaft bearing race 2 |

| q | Pulling out → Fig. |

| q | Preparing for pressing in → Fig. |

| q | Pressing on → Fig. |

| 9 - | Output shaft shim 1 |

| q | Determining thickness → Chapter |

| 10 - | Output shaft bearing race 1 |

| q | Pulling out → Fig. |

| q | Pressing on → Fig. |

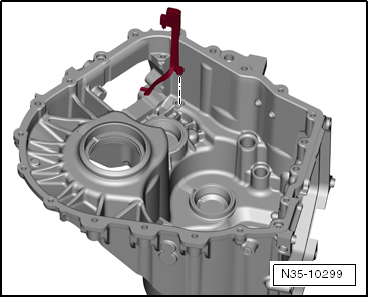

| 11 - | Bearing for the inner input shaft |

| q | Remove to press out retaining ring |

| q | Press in »new« bearing → Fig. |

| 12 - | Circlip |

| q | Always replace. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|