Leon Mk1

|

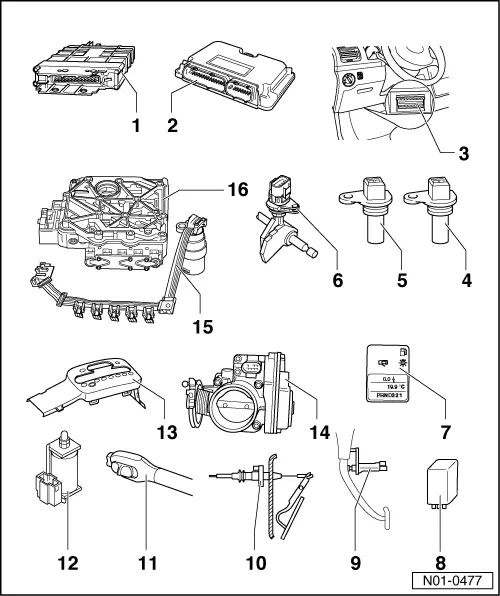

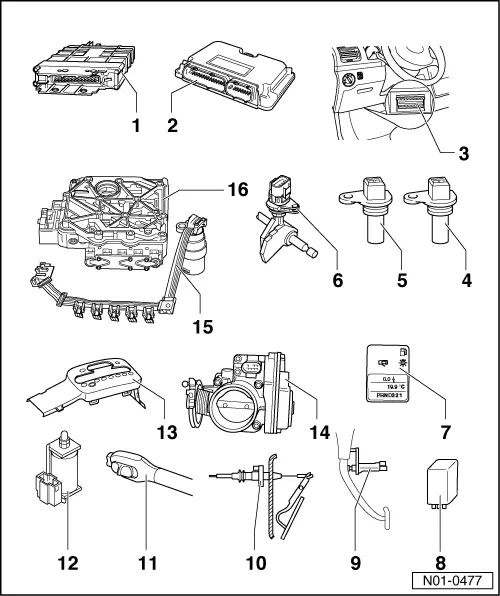

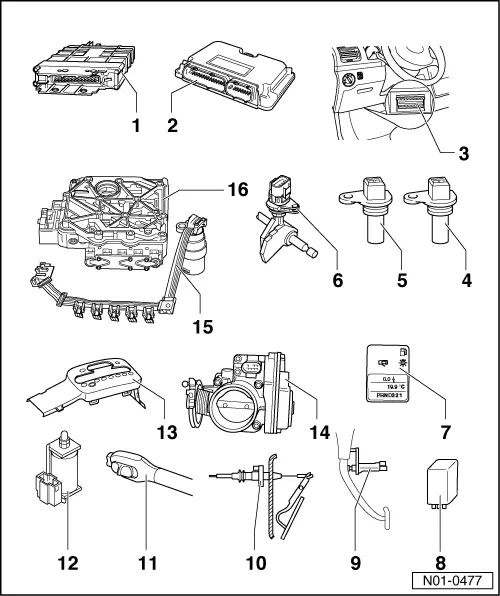

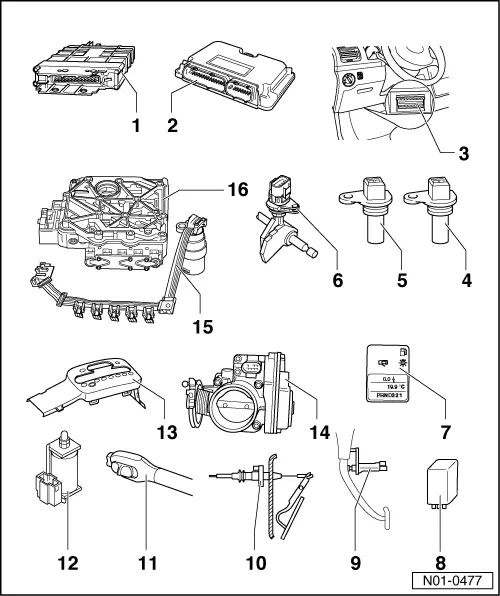

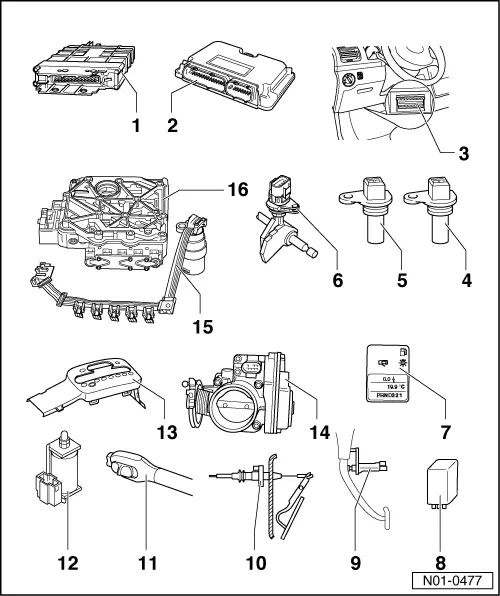

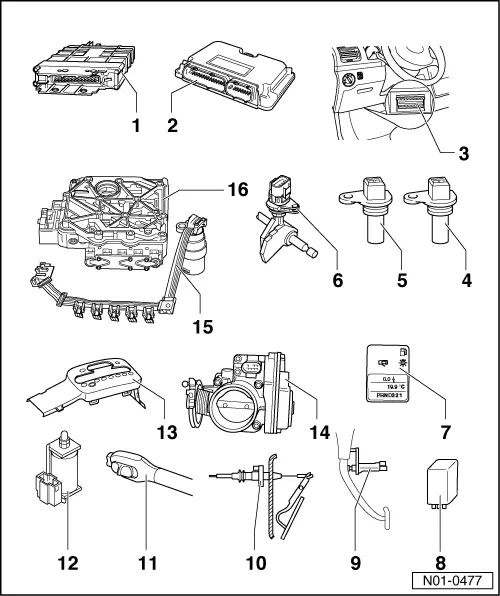

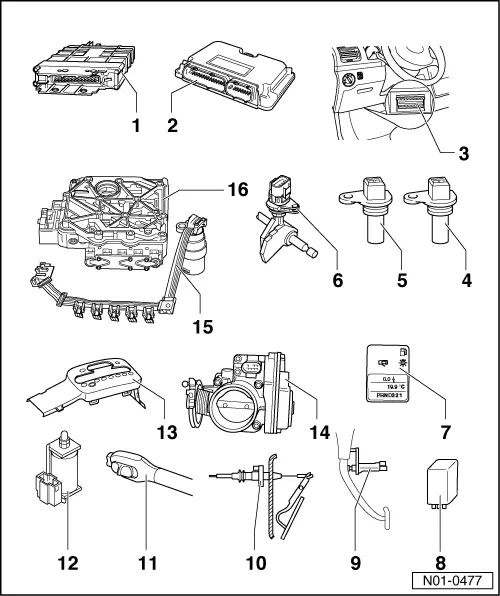

Locations of electrical/electronic components

Locations of electrical/electronic components

|

|

|

|

|

=> Repair group 23; of the respective engine code => Repair group 24; of the respective engine code If engine or gearbox control units are replaced, the system must be brought to basic setting , Initiating basic setting.

|

|

|

=> Automatic gearbox 099 - 4-speed; Repair group 38; Dismantling and assembling parking lock

=> Automatic gearbox 099 - 4-speed; Repair group 38; Dismantling and assembling parking lock

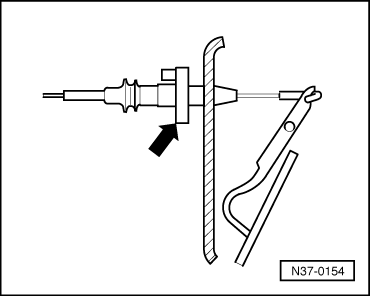

Do not interchange connector T2 for senders -G38- and -G68- |

|

|

=> Automatic gearbox 099 - 4-speed; Repair group 38; Dismantling and assembling parking lock

|

|

|

=> Electrical system; Repair group 94; Steering column switch; Servicing steering column switch

|

|

|

|

|

|

=> Automatic gearbox 099 - 4-speed; Repair group 38; Removing and installing valve chest

|

|

|

|

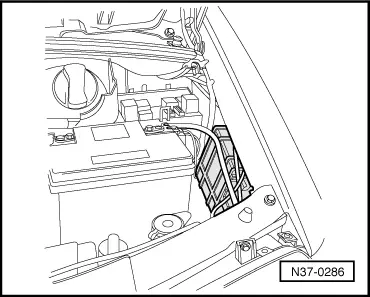

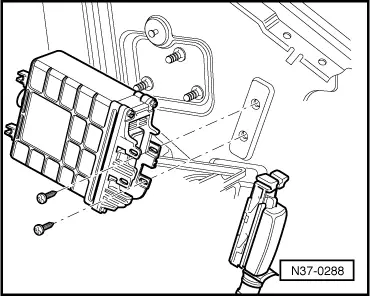

→ Fig.1 Location of automatic gearbox control unit -J217- The control unit is located in the engine compartment, left. |

|

|

|

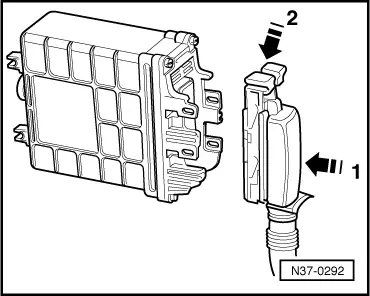

→ Fig.2 Removing automatic gearbox control unit -J217-

|

|

|

|

→ Fig.3 Installing automatic gearbox control unit -J217-

|

|

|

|

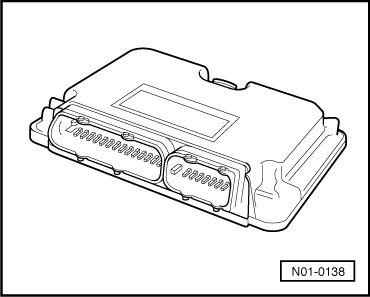

→ Fig.4 Engine control unit for vehicles to 05.00 Location: The control unit is located behind dash panel. Removing and installing control unit |

|

|

|

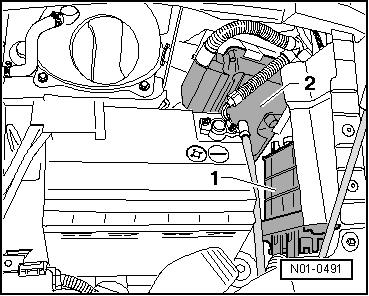

→ Fig.5 Engine control unit for vehicles from 06.00 Location: The control unit -2- is located in engine compartment, left. Removing and installing control unit |

|

|

|

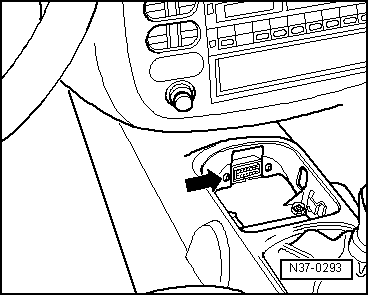

→ Fig.6 Diagnostic connection for vehicles to 05.00 Location: The diagnostic connection -arrow- is located in centre console.

|

|

|

|

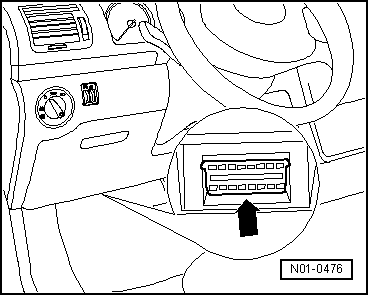

→ Fig.7 Diagnostic connection for vehicles from 06.00 Location: The diagnostic connection -arrow- is located under stowage compartment on driver's side. |

|

|

|

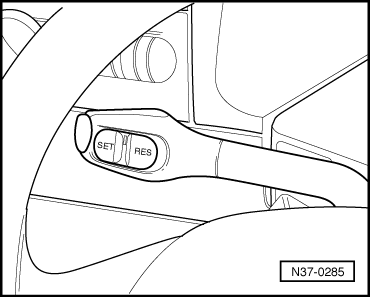

→ Fig.8 Cruise control system switch -E45- Location: Cruise control switch is located on steering column switch. Removing and installing cruise control switch => Electrical system; Repair group 94; Steering column switch; Servicing steering column switch |

|

|

|

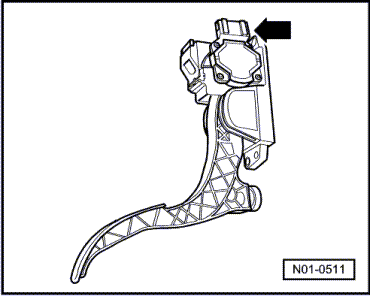

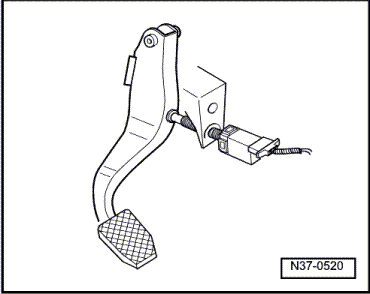

→ Fig.9 Brake light switch -F- Location: Brake light switch (arrow) is located on pedal cluster. Removing and installing brake light switch |

|

|

|

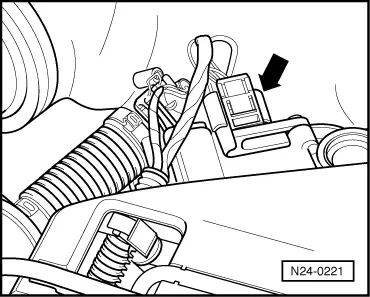

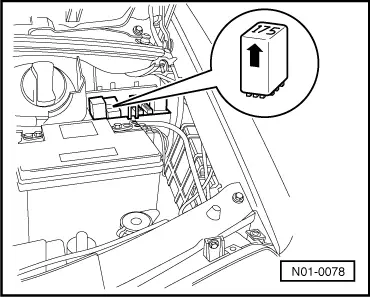

→ Fig.12 Relay for starter inhibitor and reversing light -J226- for vehicles to 05.00 Location: Relay located on relay carrier in engine compartment, left. Relay is marked with number "175" -arrow-. |

|

|

|

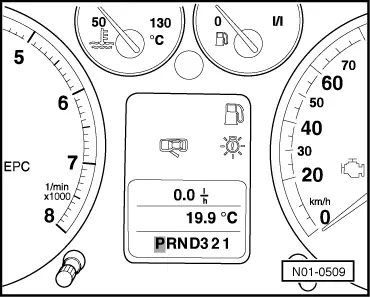

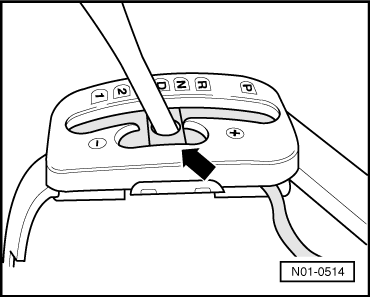

→ Fig.15 Tiptronic switch -F189-

|