| –

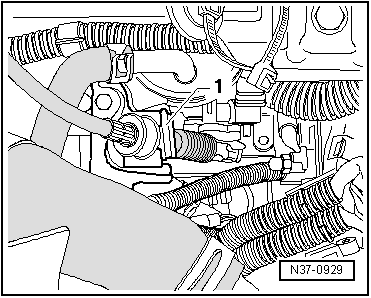

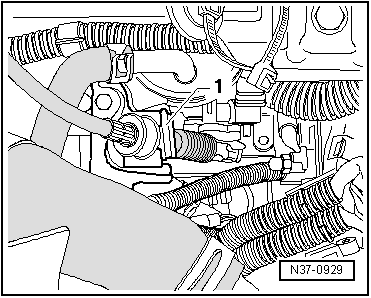

| Always replace the axle catch - 1- for the selector lever cable. |

| –

| Check the selector lever cable adjustment → Chapter. |

| –

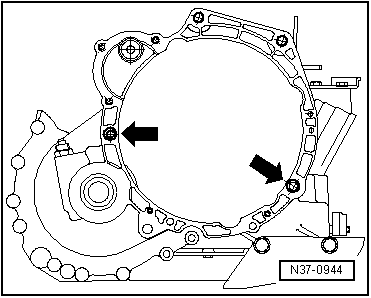

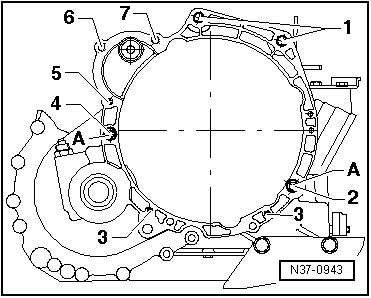

| Check the multifunction switch adjustment; and if necessary, adjust → Fig. |

| –

| Check the ATF level and top up: with the filler tube → Chapter, without the filler tube → Chapter |

| –

| Check the connectors of all the electrical connections (visually). |

| –

| Check the gear selection mechanism → Chapter. |

| –

| After connecting the battery, depending on the version, vehicle equipment will have to be encoded (encoding the radio, adjusting the clock, etc.). |

|

|

|

Note

Note