Leon Mk1

|

|

|

|

|

|

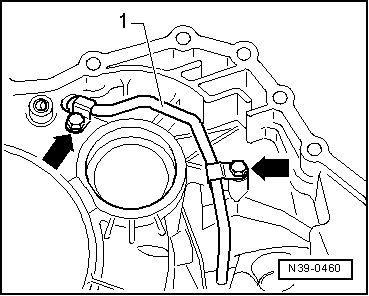

| 1 - | Torque converter casing |

| q | Removing and installing → Chapter |

| q | Oil pipe: removing and fitting → Fig. |

| 2 - | Thrust washer |

| q | For satellite |

| 3 - | Satellite |

| q | Fitting ⇒page → Fig., fig. → Fig. |

| 4 - | Thrust washer |

| q | For the planet gear |

| 5 - | Planet gear |

| q | Fitting → Fig. |

| 6 - | Threaded component |

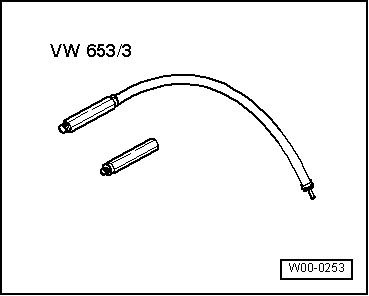

| 7 - | Tension sleeve |

| q | To hold the satellite shaft |

| q | Extract and replace with a punch |

| 8 - | Satellite shaft |

| q | Extract by striking with a punch |

| q | On fitting, do not damage the thrust washers |

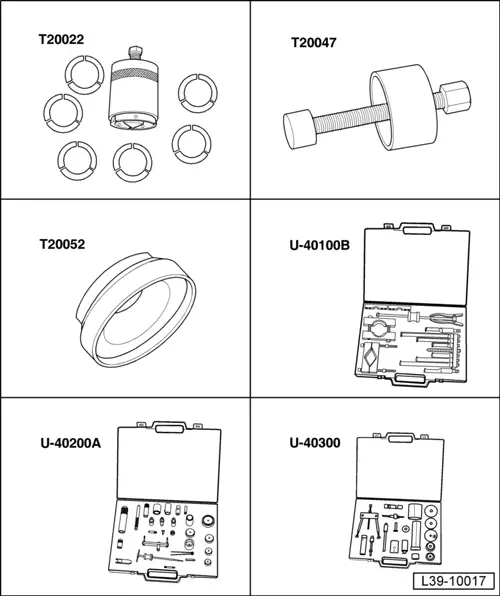

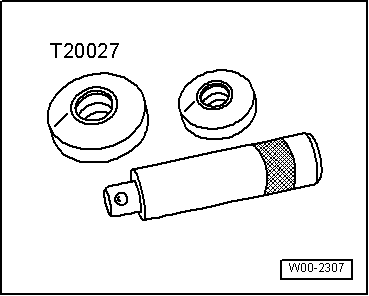

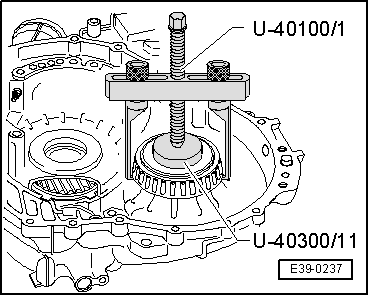

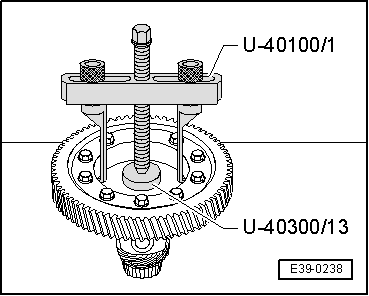

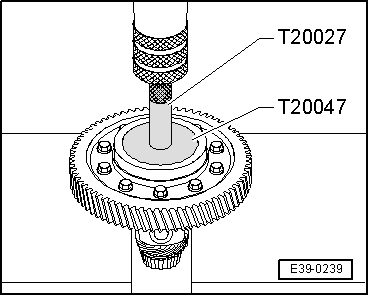

| 9 - | Outer ring of roller bearing |

| q | Remove → Fig. |

| q | Fit into the differential housing → Fig. |

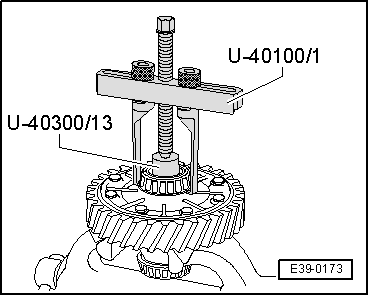

| 10 - | Inner ring of roller bearing |

| q | Remove → Fig. |

| q | Fit into the gearbox casing → Fig. |

| 11 - | Gearbox casing |

| q | Differential: removing and fitting → Chapter |

| 12 - | Bolt |

| q | 80 Nm |

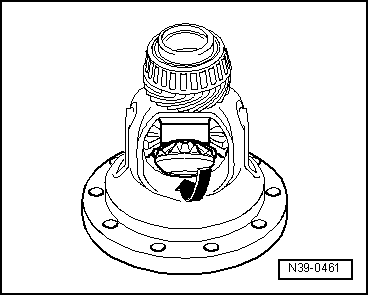

| 13 - | Differential casing |

| 14 - | Crown |

| q | Number of teeth |

| 15 - | Speedometer drive sprocket |

| q | Fit the projections of the drive sprocket into the groove in the differential casing, flat side facing outwards |

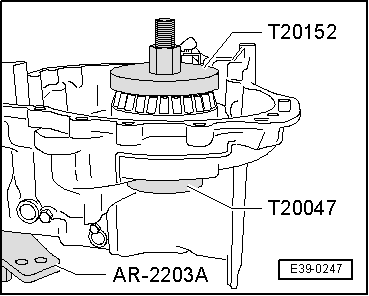

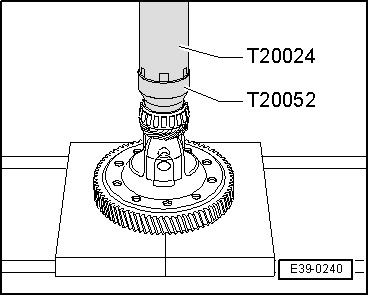

| 16 - | Inner ring of roller bearing |

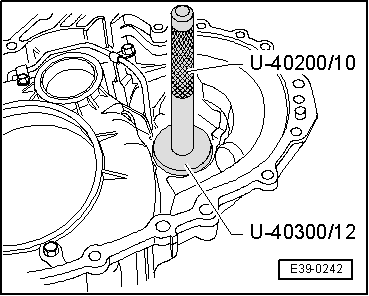

| q | Remove → Fig. |

| q | Insertion → Fig. |

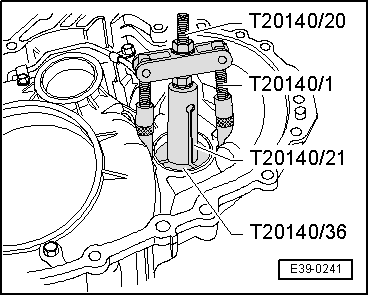

| 17 - | Outer ring of roller bearing |

| q | Remove → Fig. |

| q | Insertion → Fig. |

| 18 - | Shim |

| q | Determine thickness → Chapter |

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|