Leon Mk1

|

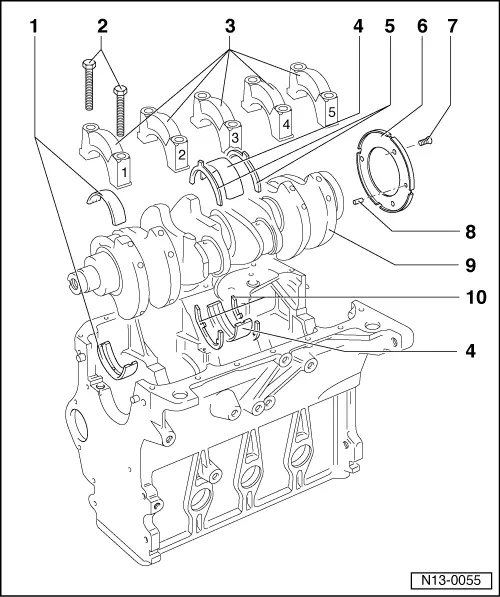

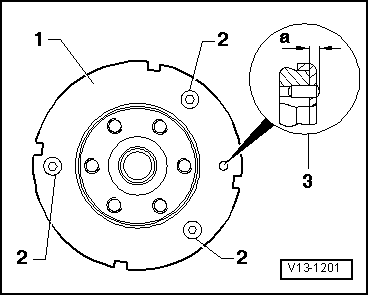

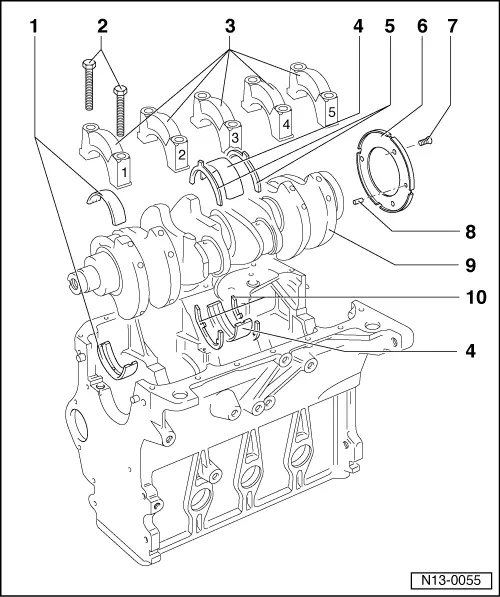

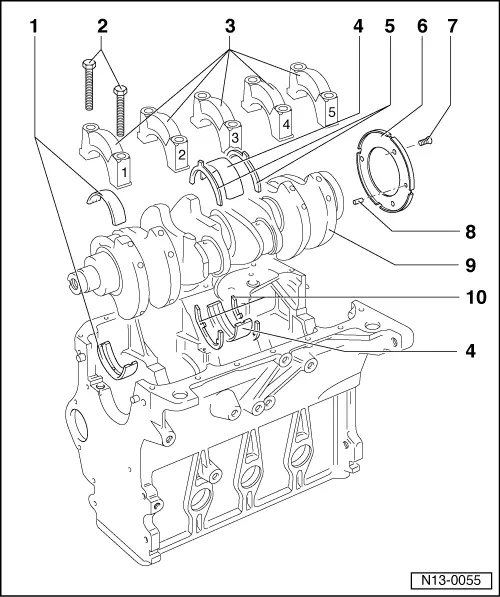

Removing and installing crankshaft

Removing and installing crankshaft

|

|

|

|

|

|

|

|

|

|

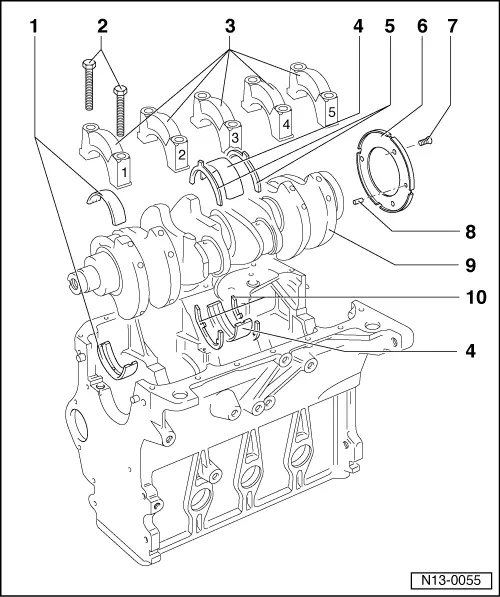

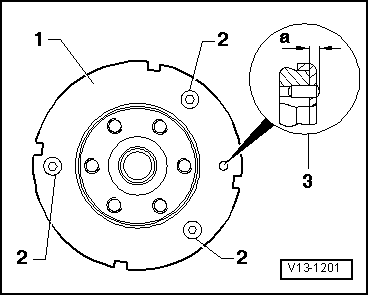

→ Fig. 1 Checking fitted pin projection out of crankshaft Dowel pin projection -3- out of crankshaft |

|

Removing and installing crankshaft

Removing and installing crankshaft

|

|

|

|

|

|

|

|

|

|

→ Fig. 1 Checking fitted pin projection out of crankshaft Dowel pin projection -3- out of crankshaft |