Leon Mk1

|

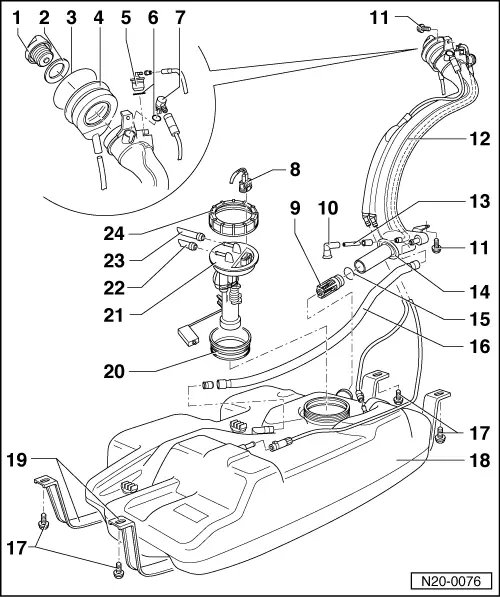

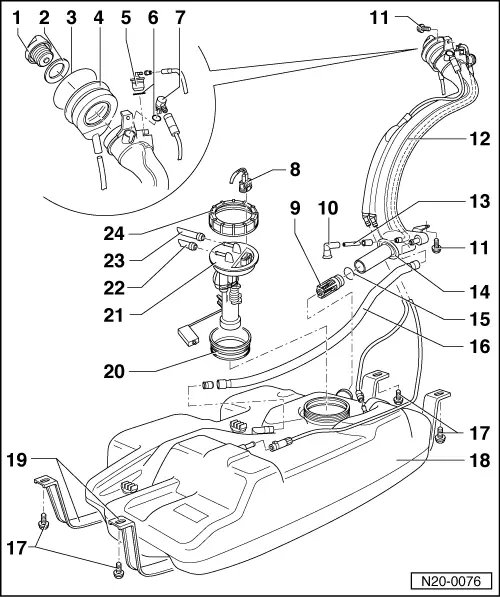

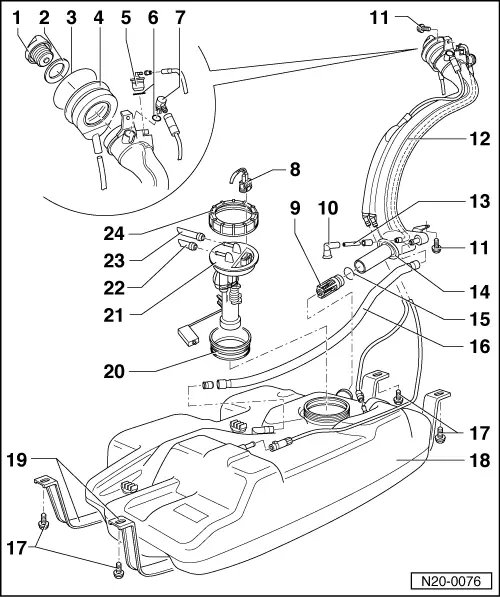

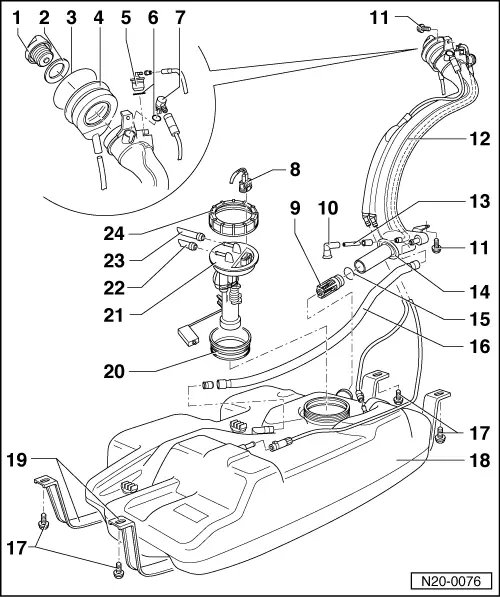

Removing and installing parts of fuel supply system

Removing and installing fuel tank with its attachments

|

|

|

|

|

|

|

|

|

|

|

|

|

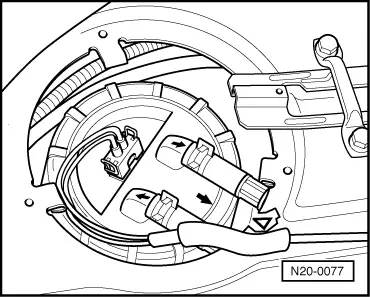

→ Fig. 1 Installation position of fuel gauge sender Marking on the flange must align with marking on the fuel tank. |

|

|

|

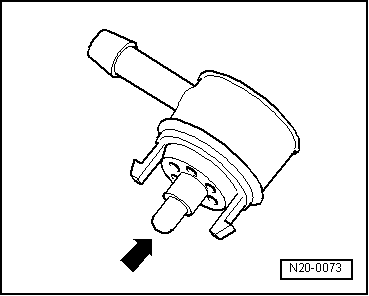

→ Fig. 2 Checking vent valve Valve in rest position: Closed Valve pushed in direction of arrow: Open |