Leon Mk1

|

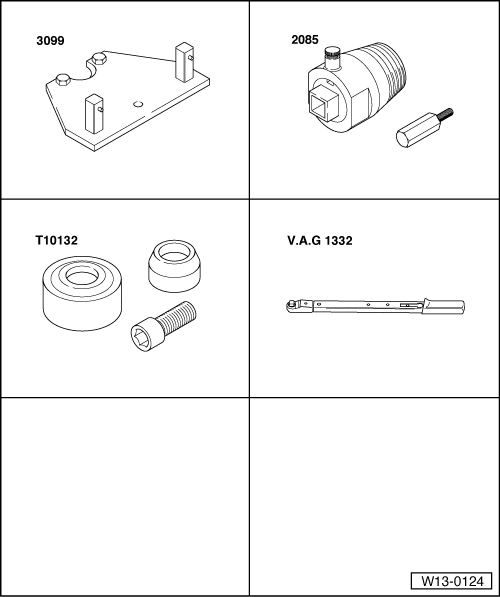

Removing and installing sealing flanges and flywheel/drive plate

Renewing crankshaft oil seal -belt pulley end-

|

|

|

|

|

|

|

|

|

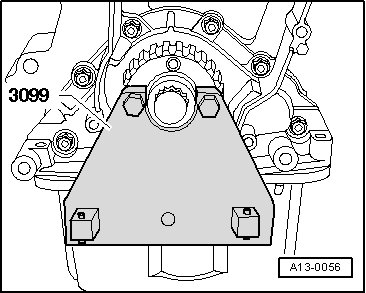

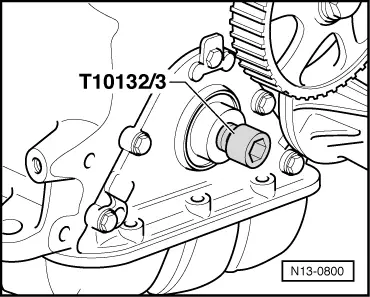

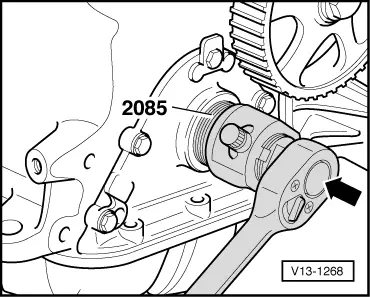

Installing |

|

|

|

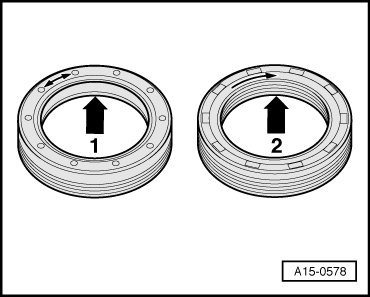

Note: → A PTFE seal (Teflon) -2- has been introduced gradually to replace the coil spring seal -1-. The seal has a wider sealing lip. PTFE seals are fitted free of oil or grease. If a PTFE seal is installed then only such a seal may be used as a spare part.

|

|

|

|

|

|

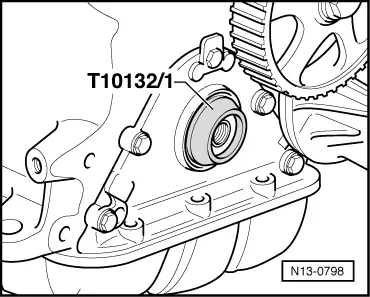

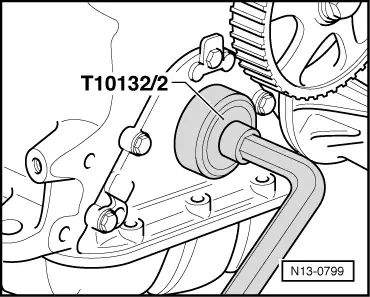

Note: Thread and shoulder must be free of oil and grease. When installing toothed belt and adjusting valve timing => Page 13-16.

|