Leon Mk1

|

Removing and installing engine

Notes on removing

Note: Check whether a coded radio is installed as during the forthcoming work sequences the battery earth strap must be disconnected. Obtain radio code first if necessary. |

|

|

|

|

|

=> Repair group 24; Servicing injection system; Dismantling and assembling air cleaner. Warning!

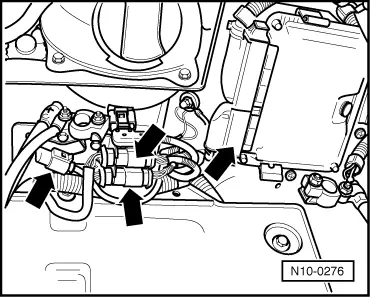

Fuel supply system is under pressure! Before loosening hose connection wrap a cloth around the connection. Then release pressure by carefully pulling hose off connection. |

|

|

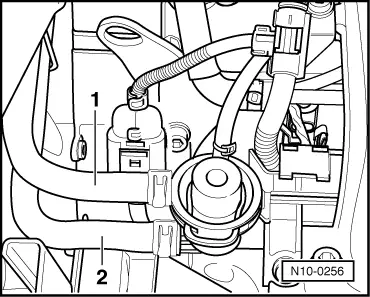

Vehicles with manual gearbox

=> Running gear, Axles, Steering; Repair group 40; Removing and installing drive shaft Vehicles with automatic gearbox

=> Running gear, Axles, Steering; Repair group 40; Removing and installing drive shaft Vehicles with air conditioner

Continuation for all vehicles

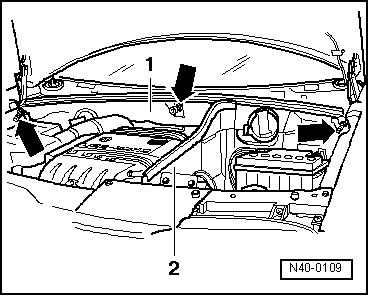

=> General body repairs, Exterior; Repair group 50; Body front; lock carrier service position

|

|

|

|

|

|

|

|

|

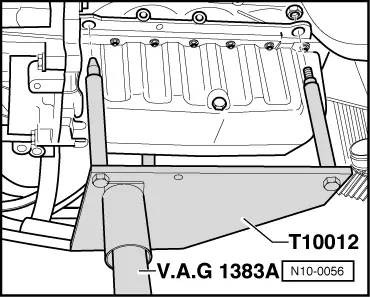

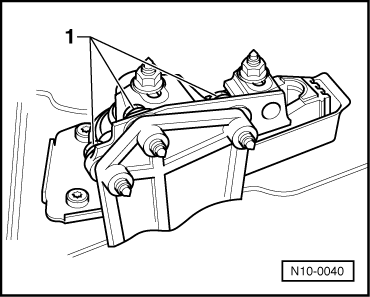

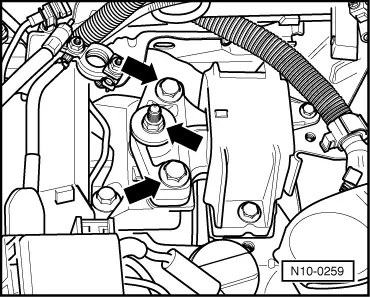

Note: To remove securing bolts use ladder VAS 5085.

Note: Engine and gearbox must be guided carefully when lowering to prevent damage to the bodywork, hoses and wiring. |