Leon Mk1

|

Dismantling and assembling engine

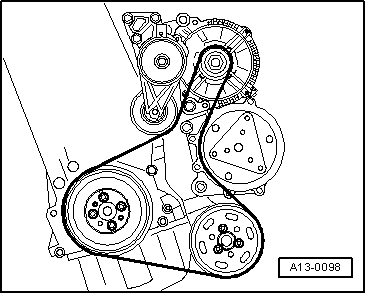

Removing and installing ribbed belt

|

|

|

|

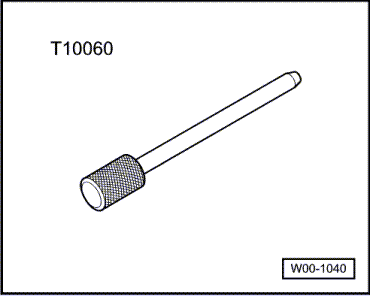

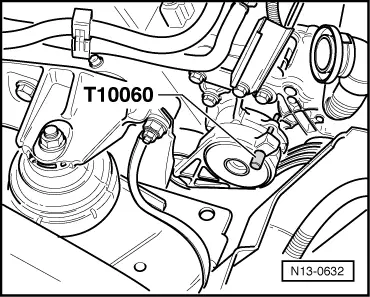

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

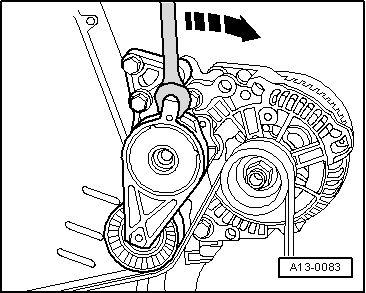

Work sequence

=> Repair group 24; Servicing injection system; Dismantling and assembling air cleaner.

|

|

|

|

|

|

Installing ribbed belt

Notes:

After completing repairs always:

|

|

|

|

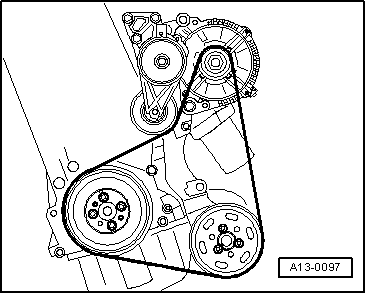

→ Belt drive without air conditioner compressor |

|

|

|

→ Belt drive with air conditioner compressor Note: Engines with an air conditioner compressor are fitted with a double ribbed belt. |