|

Exhaust gas recirculation system

Checking exhaust gas recirculation valve with temperature sensor

Special tools, testers and auxiliary items

-

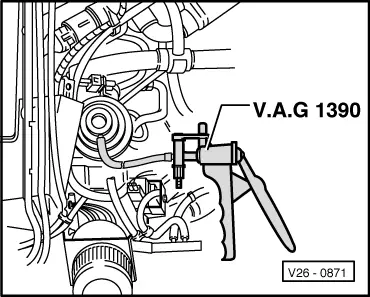

◆ Hand vacuum pump V.A.G 1390

-

◆ Fault reader V.A.G 1551 or vehicle system tester V.A.G 1552 with cable V.A.G 1551/3

-

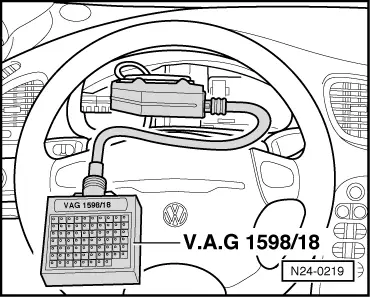

◆ Test box V.A.G 1598/18

-

◆ Hand multimeter V.A.G 1526 or multimeter V.A.G 1715

-

◆ Adapter set V.A.G 1594

-

◆ Current flow diagram

Check conditions

-

● Vacuum pipes and hose connections free of leaks.

-

● Vacuum pipes not blocked/kinked.

-

● Engine oil temperature at least 50 °C

Test sequence

-

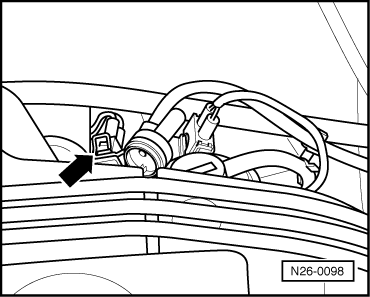

‒ Connect fault reader V.A.G 1551 (V.A.G 1552) and select engine electronics control unit (address word 01); carry out selection at idling:

=> Repair group 01; Self-diagnosis; Connecting fault reader V.A.G 1551 and selecting engine electronics control unit

|