|

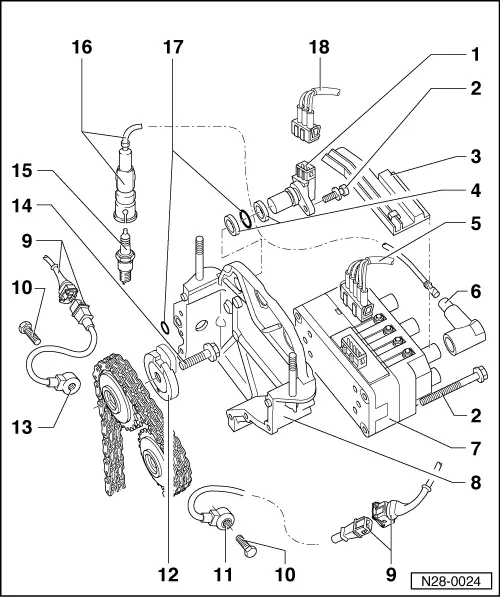

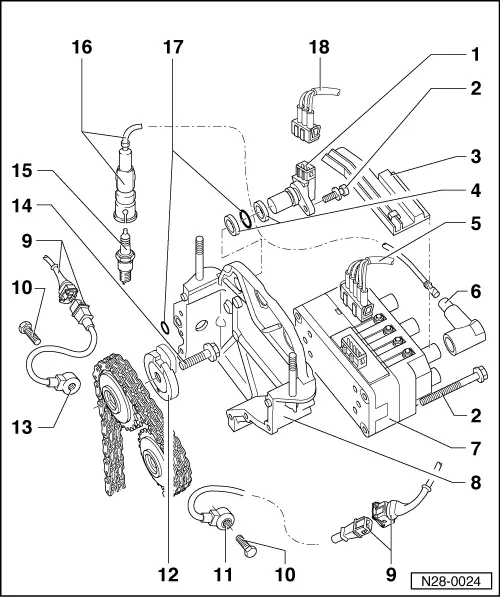

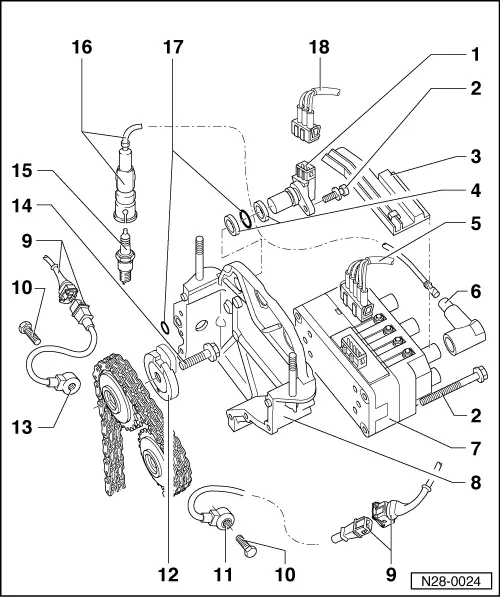

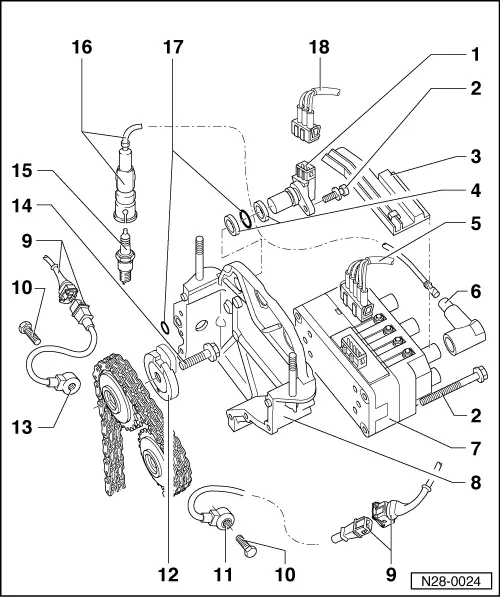

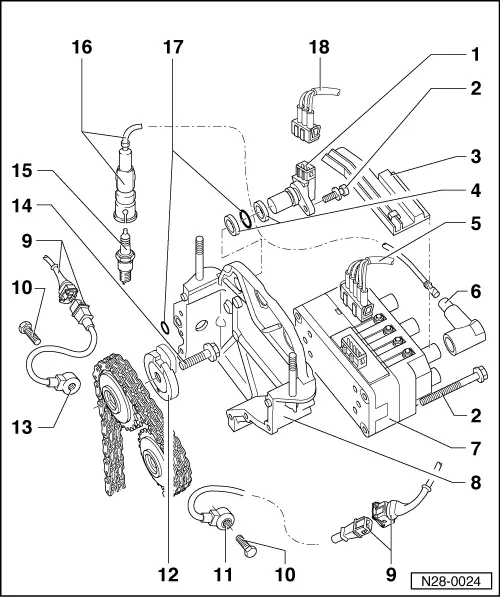

Motronic injection and ignition system

Servicing ignition part

Notes:

-

◆ Only the components which specifically relate to the ignition system are dealt with here. For the other components of the injection and ignition system:

=> Repair group 24

-

◆ The injection and ignition system control unit is equipped with self diagnosis.

-

◆ Components marked with a * are checked via the self diagnosis.

-

◆ Before carrying out repairs and for fault finding, interrogate fault memory , interrogating and erasing fault memory

-

◆ For trouble-free operation of the electrical components, a voltage of at least 11.5 V is necessary.

-

◆ If the engine starts, runs for a short period and then stops, after fault finding, repairs or component tests, then the fault may lie with the immobilizer which is blocking the engine control unit. The fault memory must be interrogated and if necessary the control unit matched => Page 24-84.

-

◆ During some checks it is possible that the control unit will recognise and store a fault. Therefore after completing all checks and repairs the fault memory must be interrogated and if necessary erased.

=> Page 01-10, interrogating fault memory

Safety precautions => Page 28-8

Test data, spark plugs => Page 28-9

|