Leon Mk1

|

|

Test sequence

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

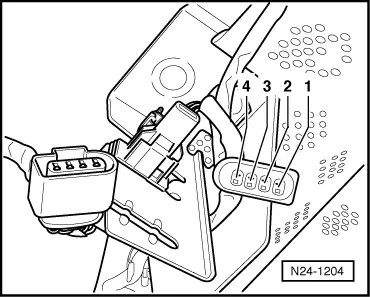

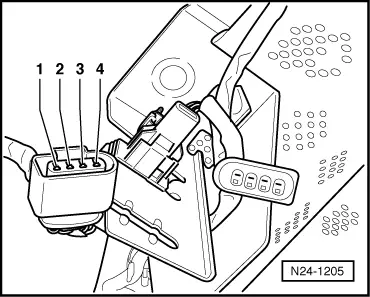

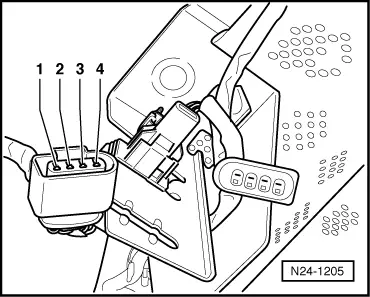

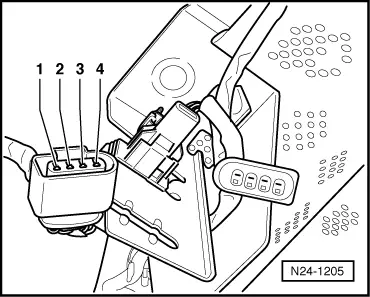

| → Indicated on display: (1...4 = Display zones) |

|

||

If the display does not indicate as described:

|

|

|

|

|

|

If it is determined that probe heating has an open circuit:

|

|

|

|

If probe heating has continuity:

If no voltage is present:

=> Current flow diagrams, Electrical fault finding and Fitting locations binder If the specification is obtained: |

|

|

If the specification is not obtained:

|

|

|

|

|

|

If no wiring fault is detected:

|