Leon Mk1

|

Note!

Note!

|

|

|

|

|

|

Note!

Note!

|

|

|

|

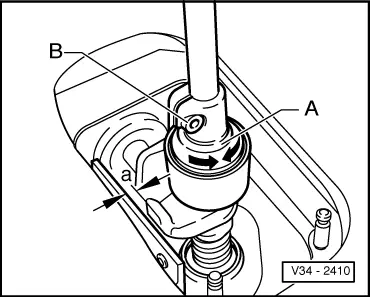

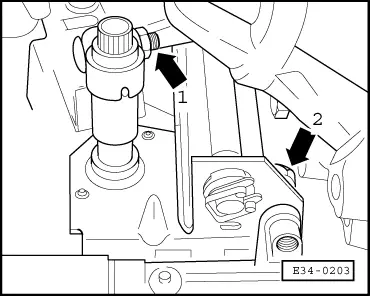

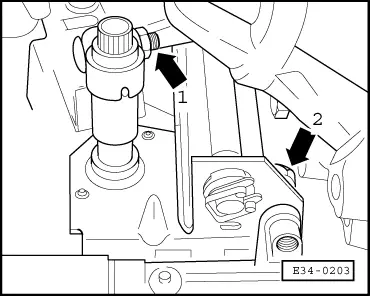

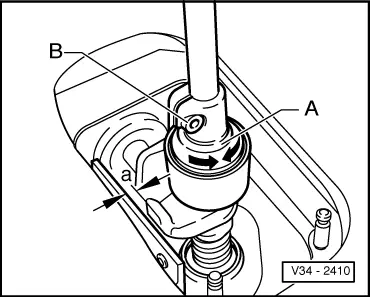

| Control rod clamp | 20 Nm |

|

|

|

|

|

| Eccentric securing bolt | 2 Nm |

|

Note!

Note!

|

|

|

|

|

|

Note!

Note!

|

|

|

|

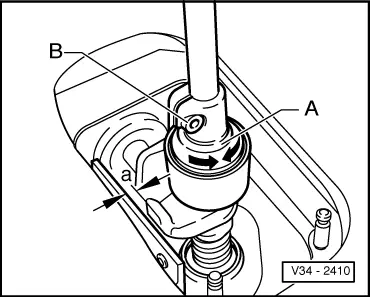

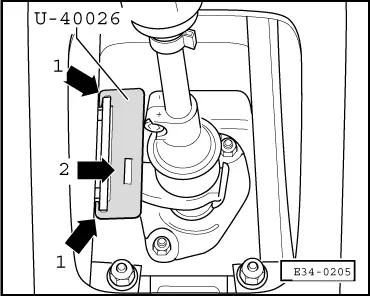

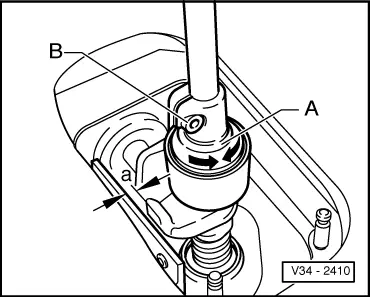

| Control rod clamp | 20 Nm |

|

|

|

|

|

| Eccentric securing bolt | 2 Nm |