| –

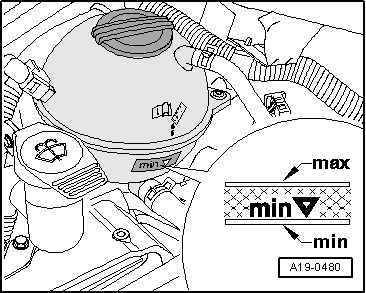

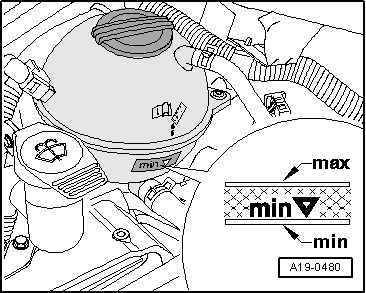

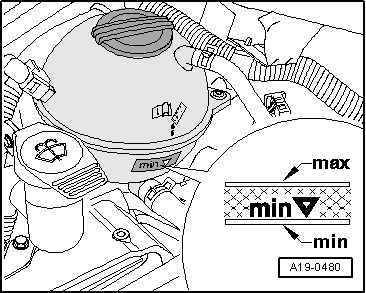

| Top up coolant to „max“ mark. |

| –

| Start the engine. Let the engine run for about 3 minutes at approx. 2000 rpm. |

| –

| Then run engine at idling speed until radiator fan cuts in. |

| –

| Check coolant level and top up any missing coolant, if necessary. When the engine is at normal operating temperature, the coolant level must be at the top mark, and when the engine is cold, in the middle of the shaded area. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note