| –

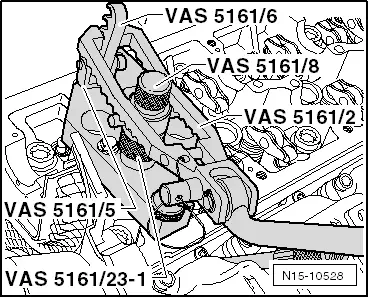

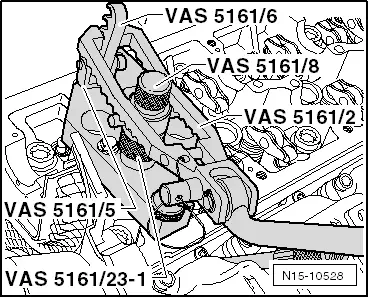

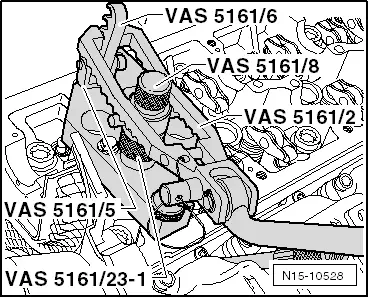

| Insert installation cartridge -VAS 5161/8- into guide plate again. |

| –

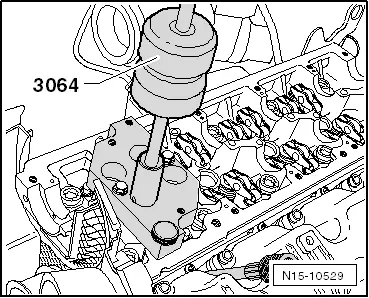

| Lower the pressure fork and pull towards the knurled screw and at the same time turn towards the left and right. Now the valve cones are inserted. |

| –

| Release pressure fork with knurled screw still in pulled position. |

| Installation is carried out in the reverse sequence; note the following: |

Note | t

| After installing cam shaft, the engine must not be started for approx. 30 minutes. The hydraulic elements should be allowed to sit in place (if not, the valves may press on the cylinder). |

| t

| After working on the valve gear, turn the engine carefully at least 2 rotations to ensure that none of the valves make contact when the starter is operated. |

|

|

|

Note

Note

Note

Note

Note

Note