Leon Mk1

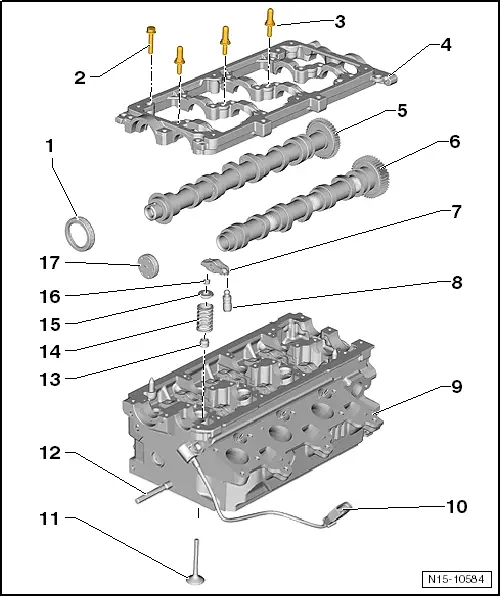

| Valve gear - exploded view |

| 1 - | Seal |

| q | Do not additionally oil or grease the oil seal sealing lip. |

| q | Before fitting, use a clean cloth to wipe off oil residue on camshaft journal. |

| q | For fitting, cover the groove in the camshaft cone (for example using sellotape). |

| q | removing and fitting → Chapter |

| 2 - | 10 Nm |

| 3 - | Guide pins |

| q | 10 Nm |

| 4 - | Retaining frame |

| q | Observe sequence when loosening and tightening → Chapter. |

| q | Seal using silicone adhesive sealant -D 176 501 A1-. |

| 5 - | Exhaust camshaft |

| 6 - | Supply camshaft |

| 7 - | Roller rocker arms |

| q | Mark the installation position |

| q | Do not mix them up |

| q | Check roller bearing for ease of movement. |

| q | Oil cam contact surface before installing. |

| 8 - | Hydraulic valve compensation element |

| q | Mark the installation position |

| q | Lubricate contact surfaces before installing. |

| 9 - | Cylinder head |

| q | See note → Chapter |

| q | removing and fitting → Chapter |

| 10 - | Hall sender -G40- connector |

| q | removing and fitting → Chapter |

| 11 - | Valve |

| q | Not to be reworked; only grinding-in permissible |

| q | Mark the installation position |

| q | Valve dimensions → Chapter |

| q | Checking valve guides → Chapter |

| 12 - | Stud |

| 13 - | Valve stem seal |

| 14 - | Valve spring |

| 15 - | Valve plate spring |

| 16 - | Valve cotter |

| 17 - | Sealing cap |

| q | Replace |

|

|

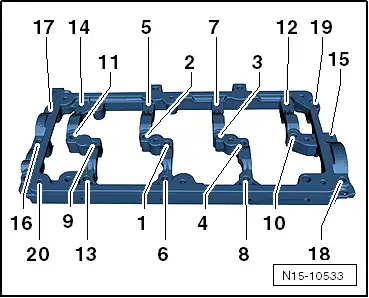

| stage: | Bolts | Tightening torque | ||

| 1. | -1 … 20- | Screw in bolts by hand until they make contact

| ||

| 2. | -1 … 20- | 10 Nm |