| –

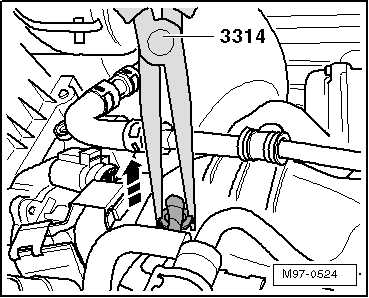

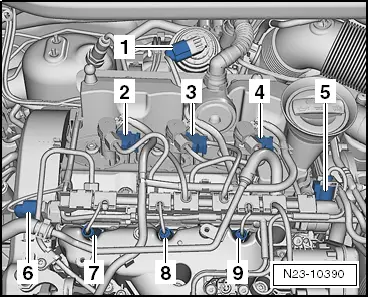

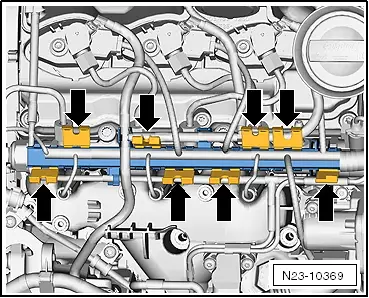

| Carefully pull connectors off glow pin plugs -in direction of arrow-. |

| –

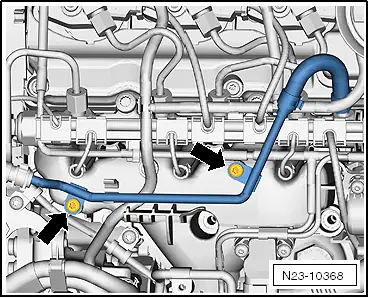

| Clean glow pin plug openings in cylinder head. It must be ensured that no dirt falls into the cylinder. |

| 1.

| Use a vacuum cleaner to remove coarse dirt. |

| 2.

| Spray brake cleaner or suitable cleaning agent into glow plug opening, let it work in briefly and blow out with compressed air. |

| 3.

| Then use an oil-soaked cloth to clean the glow pin plug opening. |

| –

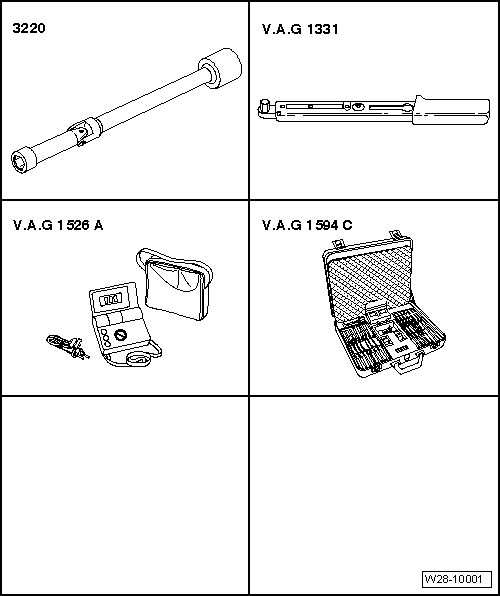

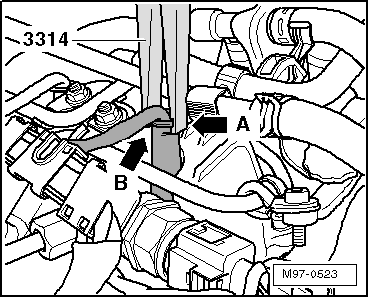

| To loosen the glow plugs, use the jointed spanner E/C 10 -3220-. |

| Installation is carried out in the reverse sequence; note the following: |

| –

| Before installing, bore in cylinder head and threads must be completely cleaned of all deposits. |

Note | Do not oil or grease thread of cylinder head bore or of ceramic glow plugs. |

| –

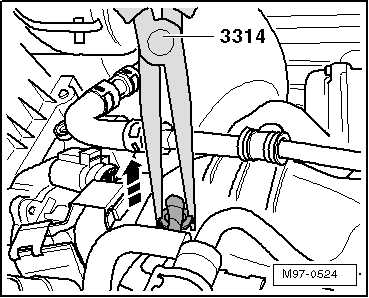

| Screw ceramic glow plugs into cylinder head by hand using U/J extension and socket -3220-. |

| –

| Then tighten ceramic glow plugs. Tightening torque: 15 Nm |

WARNING | t

| Carry out resistance test on cold engine after installing and before starting engine for first time. Carry test out on all ceramic glow plugs. |

| t

| If defective ceramic glow plug is broken, remove all fragments from engine, otherwise these can cause damage to engine. |

|

| t

| Specification: max. 1 Ω |

| –

| If the specification is exceeded, renew the defective ceramic glow plug. |

|

|

|

Note

Note

Note

Note

Caution

Caution WARNING

WARNING