Leon Mk1

| Removing and installing thermostat (extended circuit) |

| Special tools and workshop equipment required |

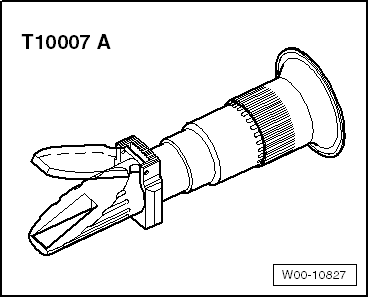

| t | Refractometer -T10007- |

| t | Drip tray for workshop hoist -VAS 6208- |

| t | Hose clip pliers -VAS 6340- |

| t | Coolant charger -VAS 6096- |

| t | Adapter for cooling system tester -V.A.G 1274/8- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

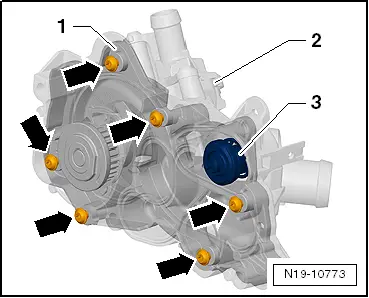

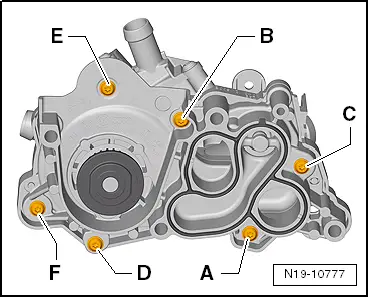

| Tightening torque: |

| Component | Specified torque . |

| Thermostat housing to coolant pump | 7 Nm |

| Coolant pump | 20 Nm |