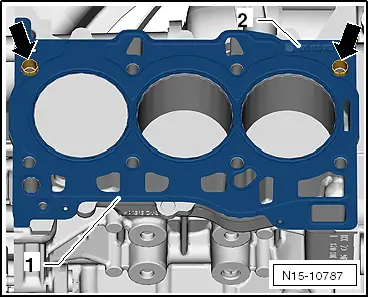

| Removing and installing cylinder head |

Note | t

| If an exchange cylinder head is installed, all the contact surfaces between the supporting elements, roller rocker fingers and the running surfaces of the camshaft must be oiled before the cylinder head cover is installed. |

| t

| The plastic packing pieces for protecting the open valves must not be removed until immediately before fitting cylinder head. |

| t

| When fitting a new cylinder head or cylinder head gasket, drain off all the old coolant and re-fill with new coolant. |

| t

| Cylinder head is being removed together with intake manifold. |

|

|

|

Note

Note

Note

Note