| –

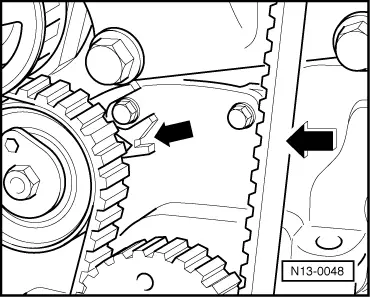

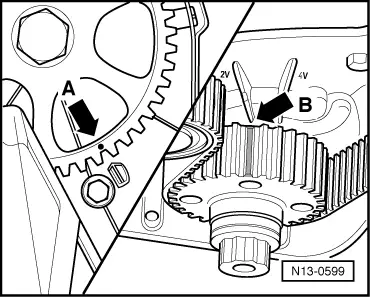

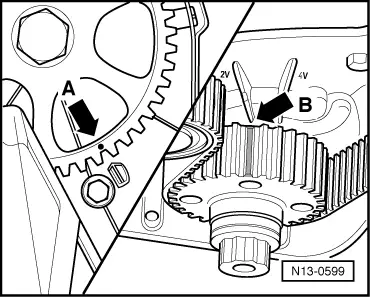

| Note the position of the tensioning roller indicator -arrow-. Press the toothed belt firmly with thumb. The indicator should move. |

| –

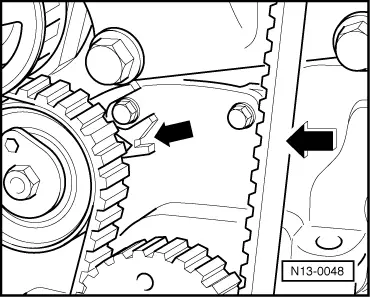

| Release tension on toothed belt. |

| –

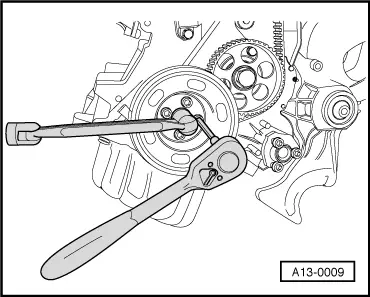

| Turn crankshaft twice fully in direction of engine rotation. |

| –

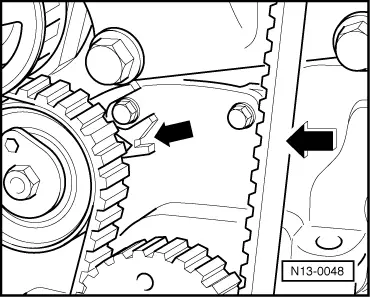

| Then check the position of the indicator. It should have returned to its original position. |

| If tensioning roller does not return to initial position: |

| –

| Replace tensioning roller. |

| If tensioning roller is correct: |

| –

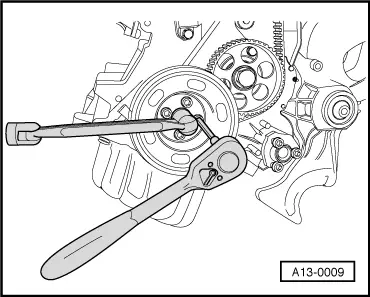

| Install toothed belt guard lower and upper parts. |

| –

| Install belt pulley/vibration damper. |

| –

| Install tensioning element for ribbed belt. |

| –

| Install the exhaust manifold protective plate. |

Note | On fitting the ribbed belt, make sure that it is correctly located on the pulleys. |

|

|

|

Note

Note

Note

Note