| Installation is carried out in the reverse sequence, when doing this note the following: |

| –

| Check clutch release bearing for wear, renew if necessary. |

| –

| Check centring of clutch drive plate, if necessary. |

| –

| Lightly grease clutch release bearing, release bearing guide sleeve and splines on input shaft with -G 000 100-. |

| –

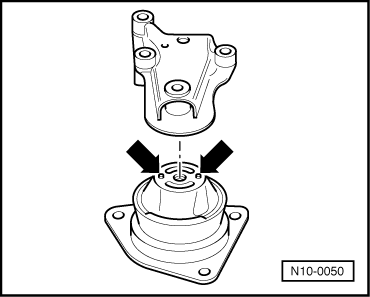

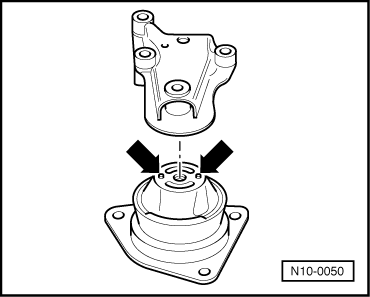

| Check whether the dowel sleeves for centralising engine/gearbox are in the cylinder block, install if necessary. |

|

|

|

Note!

Note! Note!

Note!

Note!

Note! Note!

Note!