Note! | Check whether a coded radio is installed as during the forthcoming work sequences the battery earth strap must be disconnected. Obtain radio code first if necessary. |

| –

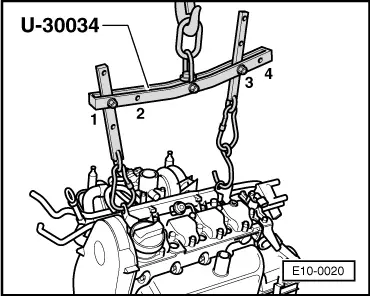

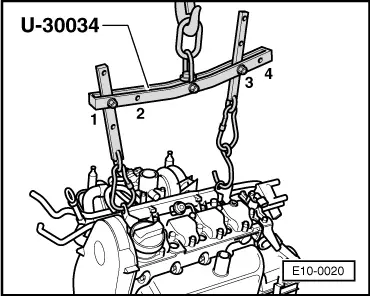

| The engine is removed forwards together with the gearbox. |

| –

| With ignition switched off disconnect battery earth strap. |

| –

| All cable ties which are opened or cut open when removing engine, must be replaced in the same position when installing engine. |

| –

| Remove battery and battery retainer. |

| –

| Open and close the expansion tank sealing cap to release pressure in cooling system. |

| –

| Disconnect all electric wires from gearbox, alternator and starter and move clear. |

| –

| Loosen or separate the following components: |

| t

| The hose from intake manifold to activated charcoal filter system |

| t

| The vacuum hose from inlet manifold to brake servo |

| t

| The connector from coolant temperature sender and oil pressure switch |

| t

| The collective connectors below the thermostat housing |

| t

| The ignition transformer and Hall sender connectors |

| t

| The engine speed sender connector |

| t

| Lambda probe connector in exhaust manifold |

| t

| The 2-pin connector from knock sensor (rear of cylinder block) |

| –

| Now separate fuel supply as well as fuel return pipes at connecting point on suspension strut turret. |

Caution | Fuel supply pipes are under pressure! Before removing from hose connection wrap a cloth around the connection. Then release pressure by carefully pulling hose off connection. |

|

| –

| Pull off/disconnect all other electrical connections as necessary from engine and lay to one side. |

| –

| Separate front exhaust pipe from exhaust manifold → Chapter, exhaust manifold, front exhaust pipe and catalyst with attachments. |

|

|

|

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!

Note!